Quicklinks

Quicklinks

As a Crane Operator, Heinrich Proes is responsible for the operation of both of HHLA’s floating cranes: HHLA III and HHLA IV. The two classic feats of engineering still play an essential role in heavy goods handling in the Port of Hamburg. HHLA IV is currently undergoing extensive renovation.

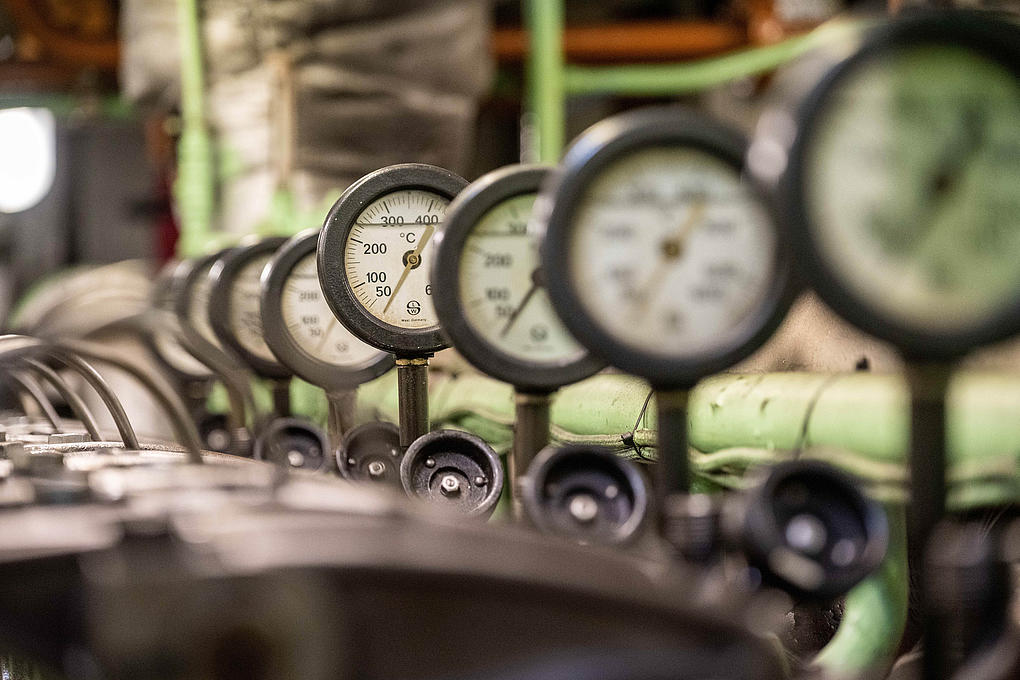

When the HHLA III or HHLA IV are put into operation, a complex organism of mechanical and electrical engineering springs to life. It is then that Heinrich Proes pricks up his ears. This is because the 38-year-old Crane Operator is able to tell from the noises and vibrations alone whether the engine and power units are running properly. And that’s very important. After all, the two floating cranes have been in service since 1941 and 1957, respectively. However, despite their venerable age, they are used almost every day to handle heavy goods in the Port of Hamburg. Such goods include enormous ship propellers, which can weigh over 100 tonnes.

“I came to HHLA’s floating cranes in 2004 almost by chance,” Proes remembers. After completing training as a docker in what is now known as the Hamburg Port Authority (HPA), the young man completed an internship with HHLA. There, he became familiar with the highly specialised department for self-propelled floating cranes with a 360-degree rotating steel lattice superstructure. Even then, the historical feats of engineering were also very flexible and offered a wide range of applications.

On the one hand, their day-to-day work included lifting heavy loads between the quayside and the ship or between ships, and on the other hand, transporting items around the port. The Voith-Schneider propellers really show what they’re made of in terms of propulsion. In addition to gigantic ship propellers, both floating cranes also transport parts for large offshore wind farms, for example. Having said that, the two floating cranes also have different areas of specialism. HHLA III can hoist loads particularly high in the air – up to 48 metres above the water’s surface. The slightly smaller HHLA IV, however, is much stronger, with a lifting capacity of 200 tonnes.

An in-depth and individual understanding of the technology in both cranes is essential to their operation. That’s why Heinrich Proes also feels privileged to have received so much expertise passed on from older colleagues at HHLA. “You need ten years to really familiarise yourself with the two specialist vessels,” the Crane Operator says, “and in doing so, I learned an incredible amount from the experienced crane operators in our team.”

Future project with history: HHLA retrofits historic floating crane for the next few years of use.

See the details and great picturesHis tasks not only include operating the crane from the driver’s cab and working in the engine room – the crane expert also regularly has to climb up to the very highest point of the jib. This is because all the bearings have to be lubricated twice a year by hand using the lubrication gun.

Another area of focus has been included in Heinrich Proes’ remit since summer 2023 – the extensive renovation of HHLA IV. “It is a sound decision by HHLA to ensure the floating crane remains in operation the future,” the Crane Operator says.

I’m always astounded at how well the technology has held up after nearly 70 years of operation.

He is currently removing an enormous roller bearing that has performed reliably since the 1950s. After repairs and a new anti-corrosive coating on the surface, a modern part of the same model will be installed. “I’m always astounded at how well the technology has held up after nearly 70 years of operation,” the Crane Operator says.

However, it’s no miracle but evidence of the long-term strategy of HHLA and a great example of its lived approach to sustainability. This is because the construction of a new crane of this scale would require enormous amounts of energy and materials. As a result, the whole Floating Crane team is rolling up their sleeves and getting involved. Soon, HHLA IV will go back into operation, and Heinrich Proes is looking forward to completing his first tasks with the renovated floating crane.

They have a lot to say – from the port, from the past, from their day-to-day work or from abroad.

Read more