Quicklinks

Quicklinks

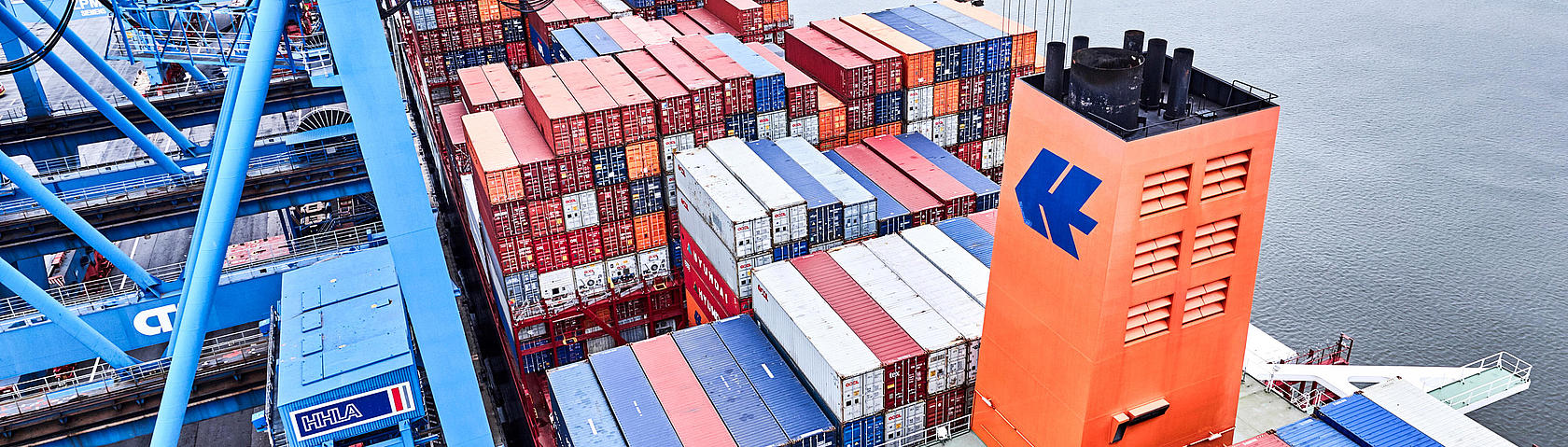

They are colourful and usually 20 or 40 feet long, which is roughly equivalent to six or twelve metres. Nearly 40 million containers are currently in transit around the world. They travel on ships, trains and trucks or are stored in factories and logistics centres. And yet, despite the colourful appearance of the steel containers, they are actually “black boxes”.

Where is my container right now? When will it arrive? Are the temperature-sensitive goods in it still properly refrigerated? Those are just some of the many questions that shippers ask shipping companies, terminals and forwarders every day – and they can only be fully answered in the rarest of cases because the necessary information is simply not available.

Ever since the container was invented in 1956, each box carries and prominently displays an individual number sign that is unique worldwide. It is initially made up of four big letters – the prefix – which identify the owner. For instance, German container shipping company Hapag-Lloyd’s prefix is HLXU. This is followed by a six-digit serial number and a control number.

With the help of this container number, every container around the world can be identified and its location on a ship or port determined. And that is about it!

This number can be recorded statically, for example during check-in at a terminal. However, it understandably cannot provide information on the current location of a container on the seven seas or on the temperature of valuable beef from South America. This was a condition that all participants along the transport chain simply had to accept for decades.

This is when movement comes into the conversation. Real-time GPS tracking and information on the temperature inside the container are just two of the functions that Hapag-Lloyd currently offers its customers with the introduction of its remote monitoring technology for reefer containers under the name “Hapag-Lloyd LIVE”.

“Especially for temperature-controlled goods like bananas, such functions can provide a decisive competitive advantage,” says Axel Hoeckrich, Managing Director of HHLA's Fruit and Refrigeration Center. Numerous Hapag-Lloyd reefer boxes, whose cargo is particularly sensitive, are handled there.

Starting in 2023, each of the company’s more than 100,000 reefer containers will be equipped with the respective monitoring and transmission transmitters. “Customers expect reliable supply chains. To ensure reliability, the sector needs to change and invest,” says Sarah Schlueter, Senior Director Niche Products at Hapag-Lloyd. “Incidentally, we have encouraged our customers to help us design our real-time monitoring tool from the very beginning. This way they receive products that are tailored precisely to their needs.”

Technologies from the “internet of things” are employed and either built into the cooling unit or the container itself. A number of sensors record the wide variety of data, which are then transferred by a mobile network antenna on the dashboard of the shipping company’s application to Hapag-Lloyd’s “Navigator” and can then be made visible to the customer.

The system was developed by Globe Tracker, a Danish company that specialises in supply chain tracking, monitoring and sensor technology. In addition, T-Mobile Austria (part of the German Telekom Group) and systems specialist Ericsson are partners in this venture.

reefer containers are intended to be equipped with monitoring and transmission devices by Hapag-Lloyd starting in 2023

“The real, unfiltered data are usually recorded and transferred every hour,” explains Olaf Habert, Director Container Applications at Hapag-Lloyd. “Even if we initially integrate the system primarily into the reefer fleet, we can provide it on request to dry container customers,” explains Habert. In the near future, it will be possible to book the LIVE features for every container transport of Hapag-Lloyd. The cost: a surcharge of USD 50 for the basic product at present.

However, the world’s fifth largest shipping company is not the only one offering this service. Competitors MSC, CMA CGM and Maersk have also introduced similar solutions for their customers. However, they don’t rely on in-house developments but use applications from the French service provider Traxens, which equips the containers of these shipping companies with its devices and then sees to the collection and transmission of the data.

This technological development also has many advantages for HHLA's container terminals. For example, the steel boxes would no longer travel separately from the data accompanying them, hopes Soenke Witt, Head of Business Partner Communications at HHLA. “We could simplify our check processes if each container sent its individual data. This would not only allow the boxes to be identified quickly and unambiguously, but we could also better organize the handling of dangerous goods and sensitive goods.” The data specialist could also imagine a warning being sent if containers are opened - possibly without authorization.

The data specialist could also imagine that the seal number of the container is transmitted and a warning is sent if containers are opened – possibly unauthorized – during transport or the seal has been tampered with.

So far, the cost of equipping “normal” boxes with transmitters is still too high. But this is not the only reason why many shipping companies still deliberately refrain from making all their containers “intelligent”. Professor Carlos Jahn, Head of the Institute of Maritime Logistics at Hamburg University of Technology (TUHH), knows the pragmatic reason for this: “A ship comes along with 20,000 containers that send information every few seconds. And it’s not just one ship, but a great many ships. The flood of information is immense!”

Prof. Carlos Jahn analyses technological trends that are changing global supply chains. Will Europe continue to play an important role?

However, Prof. Jahn is optimistic, and he is convinced that a synchronised data world awaits us in the future because “devices will become cheaper and more reliable, and we will be able to deal with more and more information. From that perspective, the vision is intriguing. However, we still have quite a way to go before it happens.”

The first step has been taken, and it happened at exactly the right time. Every status notification of a container during its journey somewhere in the world is valuable information that helps to coordinate, predict and therefore safeguard the supply chain, which has recently experienced frequent disruptions.

Whether the data come from LIVE or Traxens, containers are increasingly losing their unpopular status as “black boxes” and finally becoming transparent thanks to the new technology.