Green logistics with HHLA Pure

The future of logistics is carbon-free. It is the only way we can harmonise the rise in goods transportation with our climate protection objectives. Climate-friendly logistics with HHLA Pure is supporting this future already today. By cleverly combining a variety of solutions, we offer our customers climate-friendly transport.

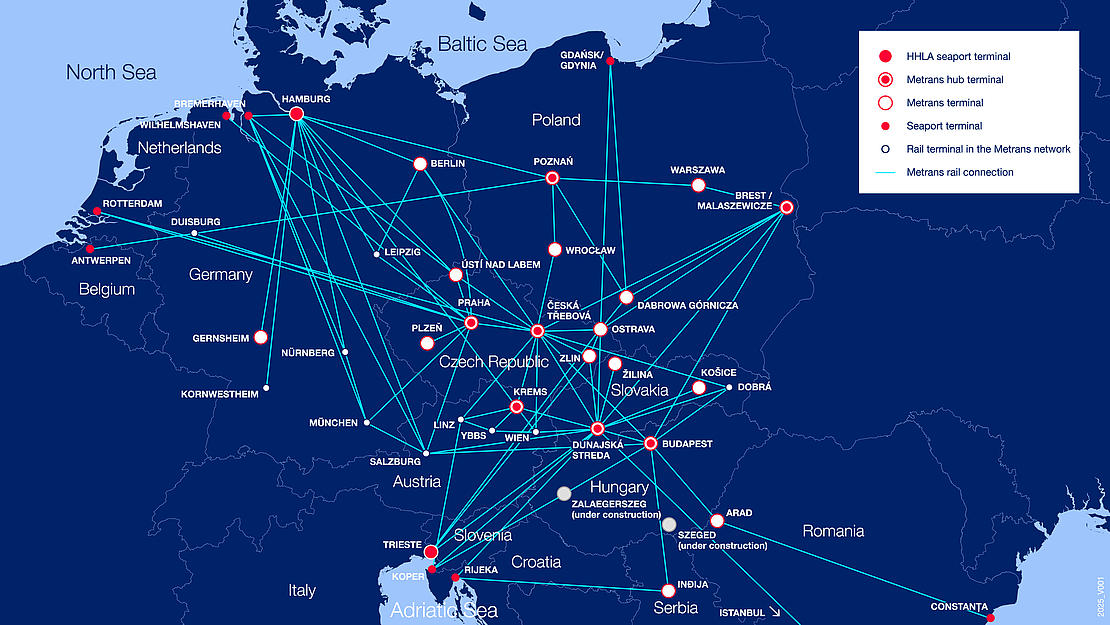

With HHLA Pure, we offer our customers climate-friendly throughput and transport of their goods from our terminals in the Port of Hamburg all the way to the European hinterland. Our Container Terminal Altenwerder is especially climate-friendly. And our rail subsidiary METRANS, one of the leading private rail operators in Europe, plays a key role when it comes to clean transportation. The future belongs to eco-friendly logistics. HHLA Pure is making this future a reality today.

Arguments for green logistics with HHLA Pure

Green logistics provides assurance

How can companies establish climate-friendly logistics processes in their supply chains and document them reliably for themselves as well as your customers? HHLA Pure is the perfect solution! We ensure that carbon dioxide emissions are eliminated or compensated at every step in our logistics chains, where possible. In light of today’s increasing demand for climate-friendly transportation, this can be an important factor for our customers when dealing with their business partners and the public.

Green logistics is sustainable

What distinguishes true sustainability? Using a resource responsibly to ensure that it remains available long into the future. This applies not only to raw materials, but also to processes such as transportation. This is why global goods flows are increasingly relying on green logistics solutions. HHLA Pure focuses on ensuring the successful implementation of every process involved in container logistics. We are continuously expanding our package of measures further to ensure that every single customer can benefit and improve their carbon footprint with HHLA Pure.

Green logistics is efficient

How can companies take advantage of the diversity within container logistics to reduce their carbon footprint? With HHLA Pure, they have access to a variety of measures for climate-friendly logistics – all from a single source! Because HHLA Pure combines numerous solutions for the logistics and warehousing processes between seaports and hinterland into a single, powerful product. And as HHLA Pure ensures that each element is perfectly tailored to the others, its potential to achieve sustainable logistics is greater than the sum of its individual innovations.

Green logistics is a tradition at HHLA

Why does our innovative HHLA Pure service have such an impressive history? Because HHLA has always recognised the importance of providing logistics services at the Port of Hamburg and at its international subsidiaries that offer customers the best and most efficient solutions available. Throughout HHLA’s diverse history, this value is something that has never changed. Which is why we have developed HHLA Pure: for this age of closely integrated, international goods flows and the highest demand for sustainable logistics processes.

Green logistics is the future

Why is HHLA Pure a project set to last? Because it already enables us to provide a compelling response to the kinds of logistics requirements companies will be dealing with more and more in the coming years! HHLA Pure not only focuses on reducing CO² emissions through an ongoing shift towards environmentally friendly electric vehicles, it also involves continuously reassessing our logistics processes and increasing their efficiency with intelligent measures.

Container handling: AGVs as intelligent power stores

The automotive industry is still waiting for electromobility’s big break. At HHLA, the electrification of all logistics processes has been running at full speed for a long time – for example with the electric and automated container transporters (AGV, right) at the Container Terminal Altenwerder (CTA). While powering up, they are able to compensate for fluctuations in the green electricity supply using their intelligent technology.

Container handling: Hybrid technology for straddle carriers

HHLA relies on a broad range of new technologies to make its container logistics eco-friendly. This includes electrified crane systems, the smart management of processes in block storage and straddle carriers with hybrid drive systems (left) at the Container Terminals Tollerort (CTT) and Burchardkai (CTB). These vehicles use the energy from braking for their electric drives, which considerably reduces fuel consumption and emissions.

Container transport: Clean through Europe with METRANS

The long-distance overland transport of goods is particularly efficient by rail. The HHLA subsidiary Metrans achieves this with electric locomotives. To make this climate-friendly logistics model work across borders, the locomotives are compatible with the energy systems of seven European countries. At the port itself, the heaviest shunting work is performed by hybrid locomotives.

Container transport: Eco-friendly connection

More efficient processes in truck logistics are brought forth by the “Fuhre 4.0” programme, which also protects resources. HHLA’s own upcoming innovations include, for example, tractor units powered by electricity. They will be used at CTA between block storage and the rail terminal.

Sustainability at HHLA

It is our aspiration to combine ecological, social and economic interests in order to make our company future-proof. We underline this with our "Balanced Logistics" sustainability strategy.

Read more

Contact persons

Volker Werner

Thomas Funk

Director Sales, Coordinator CT Odessa (Ukraine)

HHLA|SalesPhone +49 40 3088-2374

Mobile +49 176 30882374