We have played a key role in establishing technologies such as automated storage crane systems and driverless container transporters (Automated Guided Vehicles, AGVs) as a global industry standard. AGV logistics, in particular, is a crucial factor in modern automation technology, enhancing the efficiency of logistics systems. At the same time, automated processes and applications improve safety and working conditions for our employees.

Automation technologies enhance the entire logistics process. Our goal is to make the handling, transport, and storage of goods as flexible, safe, and sustainable as possible. To achieve this, we rely on automation solutions specifically designed to meet the complex demands of logistics. We are continuously modernising and automating our container terminals. In the last five years alone, we have invested over a billion euros in European port logistics.

For us, automation means creating optimal collaboration between humans and machines. We place great emphasis on developing the skills and qualifications of our employees to prepare them for new challenges. Our processes, workflows, and applications are designed to ensure seamless interaction between humans and machines - enabling flexible and intelligent logistics.

Automation of Port Operations at the Highest Level: HHLA Container Terminal Altenwerder

The HHLA Container Terminal Altenwerder (CTA) in Hamburg is a prime example of port automation. Developed in 2002 as a greenfield project on previously unused land, CTA set global standards for automated container handling with its high level of automation and has continuously integrated new technologies ever since. Thanks to innovative IT systems, the loading and unloading of container ships are carried out efficiently and precisely. Additionally, all vehicles and equipment are powered by electricity from renewable energy sources - making a significant contribution to climate-friendly logistics.

Between the container gantry cranes and the automated block storage areas, Automated Guided Vehicles (AGVs) are in operation. These battery-powered, driverless transport systems navigate autonomously, controlled by intelligent software that uses over 17,000 transponders to precisely determine their position. The AGVs independently recharge at designated charging stations, further enhancing efficiency.

Another key element of CTA is the automated block storage system, consisting of 26 storage blocks. Here, two rail-mounted gantry cranes (RMGs) of different heights handle loading and unloading. Their design allows the smaller crane to pass beneath the larger one, enabling parallel operations. Only at the handover point, where trucks are loaded and unloaded, do remote operators intervene from the control centre.

Additionally, all containers arriving at the terminal by truck or rail are automatically registered using OCR gates (Optical Character Recognition). Cameras capture the container numbers, document their condition, and log them into the internal IT systems, significantly speeding up terminal processes.

HHLA Container Terminal Altenwerder in Hamburg

Our HHLA Container Terminal Altenwerder sets new standards in automation and environmental sustainability - ensuring smooth cargo flows across Europe.

Read moreConversion into an Efficient Container Hub During Ongoing Operations: HHLA Container Terminal Burchardkai

At our HHLA Container Terminal Burchardkai (CTB) in Hamburg, we are working intensively on the industry's largest brownfield project: modernising Hamburg’s oldest container terminal while maintaining operations. The increased use of automated transport and storage systems is transforming it into a sustainable, high-performance container hub within our European network - making it one of the most advanced terminals in Northern Europe.

A key focus is the transition of the container yard to an automated crane storage system. The VC yard (operated with van or straddle carriers) has been gradually converted to automated storage blocks since 2006. At the CTB, 22 electrified storage blocks are in use, making an important contribution to the sustainable development of the terminal. The storage capacity is 45,000 TEUs. The system's efficiency is significantly enhanced by the use of three rail-mounted gantry cranes per block, allowing for much higher space utilisation.

In addition, we are gradually converting part of the diesel-electric van carrier fleet to autonomous, battery-electric AGVs while maintaining operations. A total of 116 such vehicles will replace the diesel-powered van carriers, reducing CO2 emissions by approximately 12,000 tonnes per year.

HHLA Container Terminal Burchardkai

Burchardkai (CTB) is a central hub for global trade. Almost a third of all containers passing through the Port of Hamburg are handled here.

Learn more about CTBEfficient Automated Cranes and Transport Systems with iSAM

Our subsidiary iSAM is a specialist in automation solutions. As an expert in this field, iSAM develops technologies that take industrial processes to a new level of efficiency. In port logistics, iSAM designs customised solutions for autonomous systems and processes, enabling the precise and seamless control of machines and vehicles. For example, iSAM is working on technologies that further enhance the performance of automated cranes and transport systems.

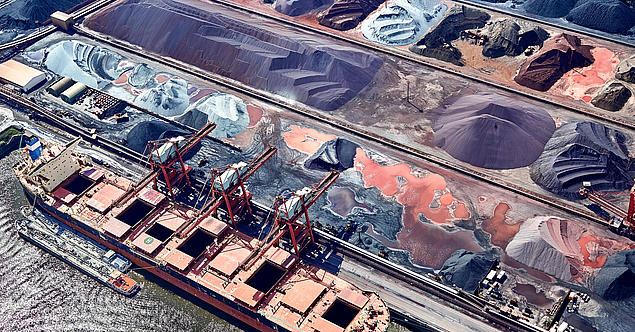

At Hamburg's Hansaport, Germany’s largest iron ore and coal terminal, iSAM has nearly fully automated operations. Handling 15 million tonnes annually, Hansaport accounts for over 10 percent of Hamburg’s total cargo throughput. Using precise 3D laser scanners and intelligent control software, iSAM’s system coordinates unloading bridges, conveyor belts, and storage equipment, significantly enhancing efficiency and safety. This technology remains unique to this day.

iSAM is currently transferring its expertise from bulk cargo handling to container terminals. At our HHLA Container Terminal Altenwerder in Hamburg, for example, iSAM is developing a new generation of rail cranes. To ensure the system can detect people and vehicles, it has been equipped with 30 real-time scanners capable of capturing up to 26 million points per second. An intelligent software continuously compares the 3D scans of the relevant environment with the expected state. If it detects unknown objects, it stops the crane. In the near future, remote operators at CTA will be able to monitor and control multiple rail cranes simultaneously.

In collaboration with FERNRIDE, we conducted a pilot project on autonomous driving at our HHLA TK Estonia terminal in the Port of Muuga. FERNRIDE is a leading platform for autonomous, electric trucking, providing innovative solutions for the logistics industry.

Following a validation phase, two automated terminal tractors were integrated into operations on a trial basis at HHLA TK Estonia. Equipped with sensors and cameras, they transported containers between the quay and storage areas via remote control, supported by numerous safety features.

Key Benefits of Automation at a Glance

Improving Working Conditions: Operating remote-controlled, automated systems offers significant advantages for our employees. They are less exposed to harsh weather conditions and physically demanding situations, can work more flexibly, and benefit from ergonomically optimised workplaces.

Enhancing Safety: Automated systems are equipped with numerous safety measures that reduce the risk of accidents. High-risk tasks in container handling, transport, and storage can be carried out without direct human intervention.

Increasing Efficiency: Automation enables faster and more resource-efficient container loading and transport. We minimise unproductive downtime for ships and trains, optimising overall terminal operations.

Achieving Climate Goals: Automated processes are software-optimised, often consuming less energy and producing fewer emissions. Equipment and machinery experience lower strain in automated mode, leading to longer service life and greater sustainability.

The Power of Networks

We connect places, companies and people – shaping the logistics of tomorrow. To achieve this, we build on intelligent solutions and the power of our networks.

Learn more