A line appears on the screen with the first field “Origin” filled in with “Jena, DE”. This is followed by a whole row of technical details, coloured time slots and finally you get to the cell containing the entry “Destination: Pasir Gudang, MY”. The subject is a container carrying optical devices that is transported from Germany to Malaysia. Something that the standard software rarely has an overview of is how much CO2 is emitted along the scheduled route.

AI is in the starting blocks, ready to optimise even complex processes

Climate-friendly or even certified climate- neutral transport is something that is being requested by an increasing number of carriers. The consumer goods conglomerate Beiersdorf also pursues an ambitious sustainability agenda. To achieve its goals, it has expanded the digital platform offered by Ulm-based company Transporeon to include all of its global sea freight. This plays “a key role in maintaining sustainable, around-the-clock operations to support our global logistics network,” says Malte Schulz, Vice President, Supply Chain EU & NA at Beiersdorf. All participants along the transport chain can continue to work with their various IT systems because the digital documents are automatically sent out with the container and can be accessed via the shared platform.

Transporeon’s AI-controlled transport logistics platforms also include a sustainability hub, which is of particular interest to eco-conscious companies. There, they can calculate their CO2 emissions down to the last pallet and then also reduce them in a targeted way. The “Carbon Visibility” solution combines the data from carriers, logistics service providers and freight forwarders and, according to the manufacturer, offers “access to all emissions data in one location in order to identify trends and inefficiencies, and to make informed decisions”. Transport management systems and telematics data can be interfaced via the application programming interface (API).

Data interfaces with poor connectivity are a hindrance

Various interfaces with poor connectivity are, however, still a hindrance to data communication – for example, for the forwarder of the optical devices from Jena. This is where the emissions data platform Shipzero comes in – which is in no way restricted to the shipping industry. Zero represents its mission “to support our customers in the decarbonisation of logistics,” says Martin Jacobs, Director Client Solutions of the Hamburg-based start-up. “There is a significant backlog in the industry, alongside the requirement to comply with lots of new regulatory standards.”

We integrate primary consumption data from transport and logistics service providers in order to calculate precise and validated CO₂ values.

On behalf of our paying customers, around 40 employees work first and foremost to consolidate and harmonise the various data resulting from a logistics or transport order. “CO2 reporting isn’t a plug-and-play model,” warns Jacobs. Sometimes simply comparing internal data from different departments is a challenge – let alone considering the national differences within a global supply chain. Shipzero can be integrated into the control and scheduling systems of its customers and receives modelled emission factors for all carriers and global transport routes. This enables the customer to work out where leverage can be applied and where there is the scope to reduce the carbon footprint of a transport. “In many cases, assumptions have to be made,” explains Jacobs. “At the same time, we are continually collecting data in order to get a more accurate picture. To do this, we integrate primary consumption data from transport and logistics service providers in order to calculate precise and validated CO2 values.” He names Sovereign Speed as an example, which uses biofuels that comply with the new HVO 100 standard. In such cases, the vehicle telematics enable precise calculations to be made regarding how high the CO2reductions would be in comparison to standard diesel on a specific route and for a specific order.

Making it simpler to book intermodal transport online

Booking and placement websites can also help to make transports more environmentally friendly. At least they do when they facilitate intermodal transport, as is the case for modility, an HHLA tech start-up. For every search request, the modility system displays a list of different transport options along with the amount of CO2 savings they can achieve in comparison to heavy goods vehicles. Forwarders can integrate rail transport more easily because they can use the platform to find more than 800 intermodal connections from 55 operators before planning and booking them online directly from the provider. “And if a consignment doesn’t arrive on time for whatever reason, a booking can be postponed to a later departure time directly via our portal,” explains Nils Funke, marketing expert at modility. “Since our platform went live, the CO2 savings from all rail transports booked via modility equate to the amount that would be captured by 172 hectares of forest per year,” he says. In future, Funke can imagine submitting extensive sustainability reports. In the longer term, the intermodal platform also wants to “draw on various funding options” to integrate inland waterway shipping and ferries throughout Europe into short sea shipping, as these are also more environmentally friendly carriers.

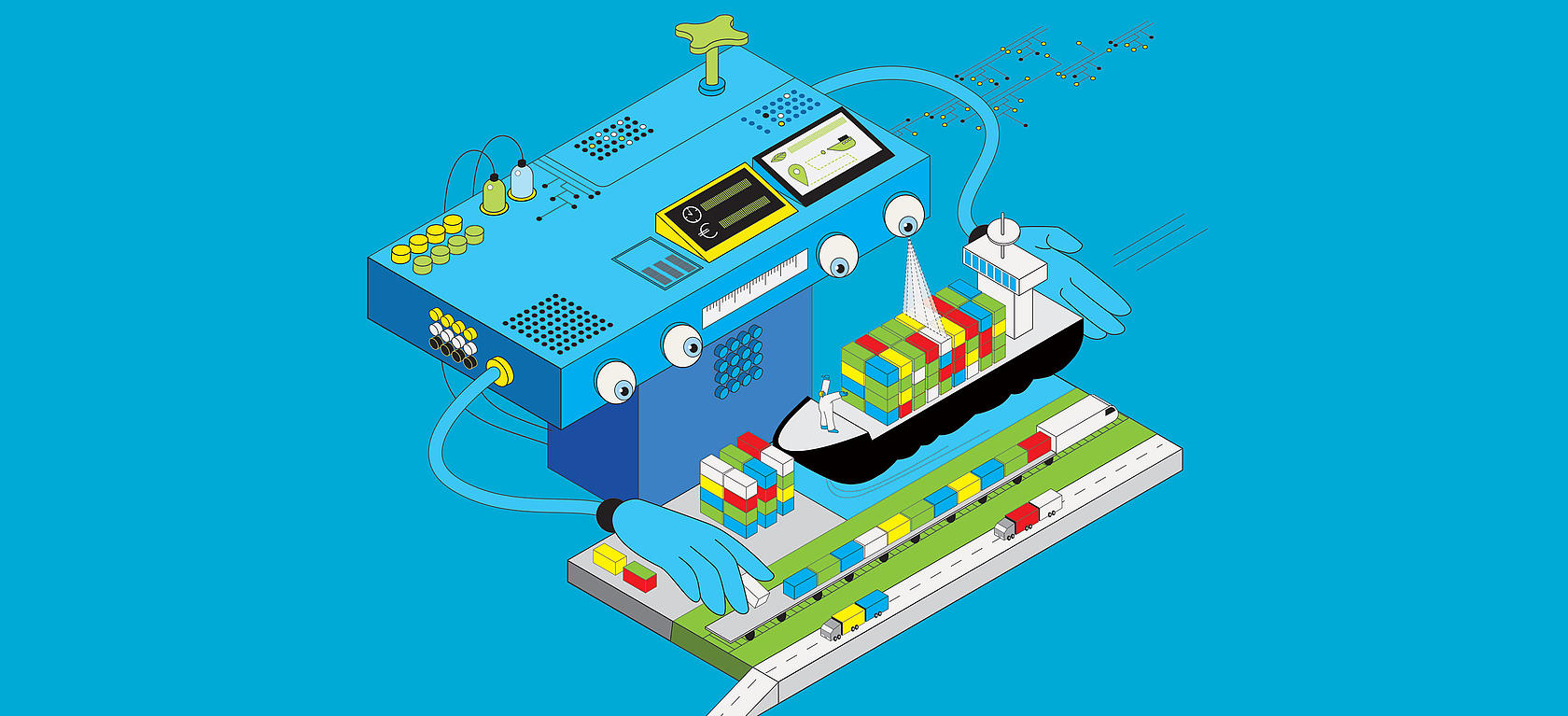

Achieving net-zero emissions in Singapore by 2050

Ambitious goals are also the focus for Singapore, the biggest maritime location in the world and Hamburg’s third largest trade partner for container handling. The port hub in South East Asia handles around one seventh of all global transshipments and is responsible for 0.11 percent of global greenhouse gas emissions. By 2050, the terminals are to achieve net zero emissions. The digital networking of the many companies operating in the port aims to help with this. The main objective is to minimise idle times for ships and vehicles, as well as to achieve shorter port calls in order to reduce the amount of pollutants entering the air of the ecosystem. The Maritime Port Authority of Singapore (MPA) launched the Maritime Single Window “digitalPORT@SG” as its central platform. It is embedded in a just-in-time (JIT) planning and coordination system. This not only allows for more efficient planning of ship calls but also services such as handling and refuelling.

In Western Europe alone, there is a port community system in every port, but linking them up is very difficult.

Singapore is growing with breathtaking speed: By 2040, the Tuas mega port, with a capacity of 65 million TEU, is set to become the largest fully automated port in the world. To achieve this, the MPA is currently testing a ship management system equipped with artificial intelligence (AI). This futuristic technology can draw on huge amounts of data to calculate future values, i.e. practically make predictions. This could also help to make complex port logistics processes more sustainable. The Port of Singapore is working at full speed and wants to launch the AI-based Next Generation Vessel Traffic Management System (NGVTMS) platform in 2025. The MPA is building the world’s largest 5G network spanning a port to serve as data infrastructure.

“It’s not just about establishing digital systems but also good connectivity between the systems,” says David Foo, Assistant Chief Executive of Operations Technology at the MPA. This aims to “lead to more efficient use of fuel and reduce unnecessary carbon emissions”. To do this, terminal operators, transshippers, freight forwarders, customs, shipping companies, rail companies and truckers all need to work together effectively. “This is already happening in ports around the world,” says Sven Daniels, Partner at the HHLA consultancy subsidiary HPC Hamburg Port Consulting. In his experience, digital platforms are no longer being used to boost productivity: “Now, sustainability targets are what it’s all about.” But he highlights one of their weaknesses: “In Western Europe alone, there is a port community system in every port, but linking them up is very difficult.” He finds overarching systems, such as a Singapore-style Maritime Single Window, the more logical choice for sustainable logistics.

Overall picture for ship calls in the Port of Hamburg

The Port of Hamburg is an industry pioneer when it comes to networking and data communication. One excellent example of the intercompany exchange of information is the HVCC Hamburg Vessel Coordination Center. Years ago, this joint venture of HHLA and Eurogate developed a similar method for managing ship calls as the one in place in Singapore. The HVCC is the central coordination point for mega-ship, feeder and inland waterway vessel traffic. Before, lots of information in the shipping industry and port business was exchanged by phone or email. “Using digital processes we aggregate data, build an overall picture of the port and plan ship calls days in advance,” explains HVCC Managing Director Gerald Hirt. When platforms such as these deliver the right data at the right time, they can make logistics more sustainable. Hirt makes a calculation: “If an 18,000-TEU ship travels from Rotterdam to Hamburg at the optimised speed of just 14 knots instead of 18 knots, we can save more than 22 tonnes of fuel and 66 tonnes of CO2.”

According to HPC expert Daniels, Hamburg and other European logistics hubs are already far ahead when it comes to sustainability, while there are “hardly any platforms and barely any data exchanged” in the USA. The same could be said of transport along the central corridor of the Iron Silk Road. The EcoTransIT World Initiative (EWI) platform does enable CO2 calculations for partial routes, but the Global Shipping Business Network (GSBN) is of the opinion that it is essential for a low-carbon future that “data for reducing emissions across the entire supply chain must be measured and tracked”. For this reason, the independent technology consortium in Hong Kong is developing a digital platform and concluded an information-sharing partnership with the Global Centre for Maritime Decarbonisation (GCMD) in Singapore in June 2023. The mutual goal is “to close the gaps in transparency between digitalisation and decarbonisation”. This is true for the whole logistics sector, which could drastically reduce its significant impact on nature and the environment if this succeeds.

Dynamic data exchange

Patrick Alexander Rugenstein juggles nautical and many other types of data every single day. In the HVCC team, intelligent software is used to coordinate most ships calling at or sailing from Hamburg for the current and following day. Which explains the many monitors. The idea of sustainable use of resources was the driving force when HHLA and EUROGATE established their joint venture in 2009. Read this article to find out why HVCC manages this with great success, and how.

Read article