Mr. Schlumberger, what are the biggest challenges for self-driving trucks in active operation at CTA?

The HHLA Container Terminal Altenwerder and its highly automated processes are the ideal test environment to try out promising technologies. Our terminals are working around the clock, 360 days a year. It takes a lot of planning to integrate new technologies into our terminal processes without disrupting operations. At CTA, we already have a lot of experience with self-driving vehicles. For 20 years, automated guided vehicles have been transporting containers here in a closed-off area between ship and block storage. The implementation of autonomous trucks is a completely different thing, because this mixes autonomous and normal vehicles. During the tests of the MAN prototype trucks, the issue of safety for our employees and other traffic participants on our terminal played a crucial role.

Why did HHLA decide to take part in the “Hamburg TruckPilot” anyway?Autonomous driving is coming! And at HHLA we have to and want to prepare. It’s in HHLA’s nature to care with this kind of development early on and proactively. We are already asking: what does it mean for our processes if self-driving trucks come to the terminal? How can we continue to ensure our efficiency for our customers? What does that mean for occupational safety? What technical requirements need to be fulfilled? We don’t just want to react to changes, we want to actively take part in shaping developments. It is not for nothing that HHLA has made it its mission to be the engine of digital transformation in the port.

Were your expectations for the project met?

Yes, we were able to collect a lot of important findings. The challenges are now much clearer, even though there’s still a long road ahead. However, it has also become clear that it is important and right for us to explore this topic at an early stage. While the project was going on, the German parliament passed a bill on autonomous driving. This is an important step for the future.

How did you feel about working with your MAN colleagues?

It was a pleasure to work with everyone. Our collaboration was great and very professional. On both sides, there was always a deep understanding of the respective requirements and challenges. Especially under the conditions of the coronavirus pandemic and the restrictions at our terminal facilities. Against this background, the final practical tests were a wonderful and successful highlight.

What are the most important findings for HHLA?

The most important result is: yes, it is possible to integrate self-driving trucks into our terminal processes. The Hamburg TruckPilot project represents the first step for this. But we are still just at the start. Safety and the acceptance of autonomous driving is an important aspect. Safety standards that apply on public streets also need to apply to our terminals. Another important point is the automated terminal/truck communication capability, which is a prerequisite for integrating autonomous transport into our operations. Now we have to continue working on this to be fit for the autonomous future.

How do you personally see the role of automation in logistics developing in the future?

Many areas of the logistics and transport sector are just in the early stages of sustainable changes compared to other large leading industries. Founders and start-ups are currently discovering logistics as a field of global proportions that is often still untapped. This is a huge opportunity for HHLA. Only those open to changes and courageous enough to actively shape the transition will survive on the market and be successful in the future. This means we must look into new technologies without prejudice in order to tackle head-on the challenges that we will face in the future. Autonomous driving and the Hamburg TruckPilot are good examples of this.

Mr. Völl, how do you remember the beginnings of the Hamburg TruckPilot project three years ago? Did you have to do a lot of convincing? What were the main hurdles for MAN Truck & Bus?

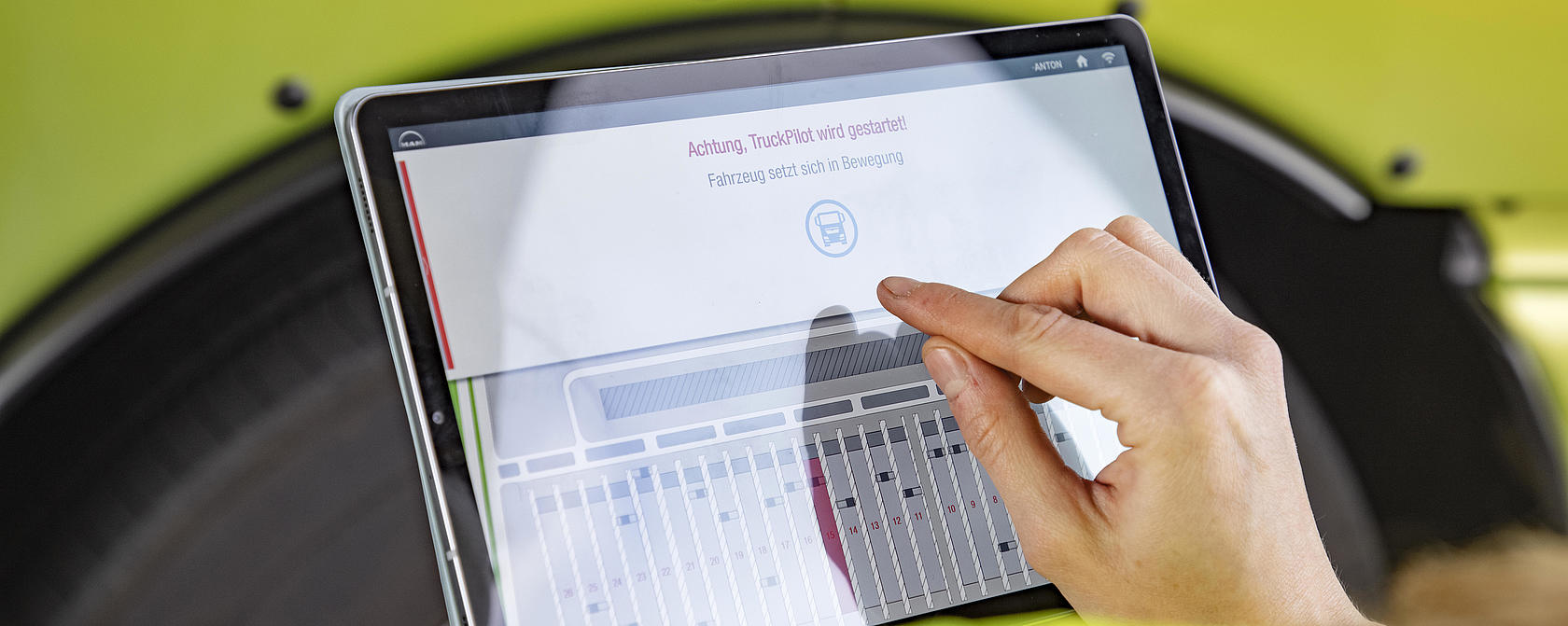

For us, Hamburg TruckPilot was our entry into automated driving. MAN Truck & Bus and the Volkswagen Group were aware of the importance of this future technology from early on. That’s why this project has opened doors. The challenge was to catch up with the technological peak very quickly. We succeeded in this unique race alongside Volkswagen Group Innovation. We were able to take over the latest automated driving technology and adapt it to the truck. To do this, we brought together leading specialists and a top-class team of experts who successfully helped Hamburg TruckPilot to achieve its goals. This team will also be the central pillar for the development of automated driving in the future. Another challenge was that we worked in regular operations at CTA rather than in artificial test conditions right from the beginning. This meant we had to adjust our parameters on-site and develop our automation system in live operation.

Would you say the project went as planned?

Essentially yes, the project went as we hoped, expected and planned: we were able to insert the pilot at CTA. The coronavirus pandemic somewhat delayed the schedule and the test conditions were even more challenging because of the hygiene requirements, but we still reached our target.

How did people on the site react to your work?

We were very obvious. Primarily to the other truck drivers, because we used the supposedly wrong lane – the automated lane at block storage, which is actually reserved for container transport between the terminal rail station and the yard. The drivers of the internal container shuttle transport were also watching us curiously. Some reacted enthusiastically, others were rather sceptical – people’s expectations of automation are still very different.

Hamburg TruckPilot wasn’t MAN’s first automation project, and it wasn’t yours either. What made the project in the Port of Hamburg special for you?The atmosphere in the port is unique; it was a great environment to test our automation technology. I remember when our prototype manoeuvred a block storage aisle for the first time. We saw that it worked, and that we could stick to the high demands for precision. And when the first container lifted off the chassis in the successful pilot operation, it was liberating!

The practical test drives were successful. What experiences is MAN Truck & Bus taking with it from Hamburg?

First of all, the lesson that our software approach works well in a limited arena like a port. We also identified challenges in the recognition of lane markings and the agility of automated steering. We made a big leap when shunting in the block storage aisle, where there were very high precision requirements and only ten centimetres of space on each side. This worked very well and we will be able to reproduce it.

How did it go working with HHLA?

Our collaboration was valuable and uncomplicated – it went very smoothly. Despite the coronavirus pandemic, HHLA did everything it could to make sure we could keep testing and finish the project in the midst of live operation. Even when repositioning or other actions on the site were necessary, we were massively supported.

What are the other milestones on MAN’s automation roadmap?

We started with platooning projects and with a technically less complex environment on the highway. Hamburg TruckPilot was therefore the next right step for us, because we were able to test the further developed automation technology on a separated area with access restrictions, where vehicles drive at low speeds. We can now build on this experience: next, we will test the automation technology between logistics hubs, on the highway and at higher speeds. The current legal situation helps us ensure we can develop the system in compliance with the law and use it in hub-to-hub transport.

Rethink. Think further. Think ahead.

How can we shape the future of logistics? Discover how innovative solutions and technologies are paving the way for more efficient and sustainable logistics.

Innovation at HHLA