Marcela Brantová is one of the few people who switched to the rail industry because of the language – not railway jargon, which is very unique, but because of her love for the complex German language. Marcela’s language talent is now not quite so important, since she has qualified as an indispensable buyer in the fast-growing METRANS Dyko Rail Repair Shop.

When she started in purchasing at Dyko in 2014, things were very different. The specialist company for train repair and maintenance was bought by the HHLA subsidiary METRANS in 2008. The locomotives driven by METRANS and now to be maintained by DYKO came from Germany – as did, of course, all the replacement parts and necessary certificates, which meant that proficiency in German was a requirement for the job.

Marcela is from the small Czech city of Kolin, where there was no job for her as a German teacher. But at Dyko, the vivacious and driven woman was able to present her qualities in such a way that she embarked on a new career path as a lateral entrant.

She was a good fit for the company that now had to reinvent itself. Of the 600 employees that had worked for the national rail operator in the days of socialist Czechoslovakia, just under 60 had stayed. They specialised in e-locomotives and wagons and learned how to maintain brand new railway technology.

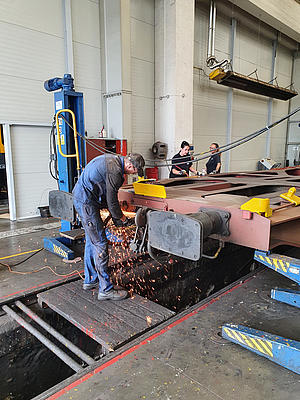

The workforce quickly grew to 160 employees again, because the expanding workshop is open to all rail and leasing companies. Anything that runs on rails must go through state-regulated inspections and maintenance. There are a variety of maintenance intervals that must be observed, meaning that every component will end up on the various test benches, some of which are equipped with state-of-the-art technology, in the airy DYKO halls one day or another.

Some components, like wheelsets and brake pads, are overhauled and repaired in Dyko’s own workshops. “This is cheaper than ordering new ones,” explains Marcela. Mostly, however, they install spare parts that her team has purchased beforehand. If a component needs to be swapped out, it shouldn’t first be ordered in a time-intensive process – the purchasing team makes sure of that almost everything can be found easily in the warehouse. Marcela orders components in advance and knows exactly where every part is located in the very clean and even heated warehouse. If she doesn’t, she can always resort to the computer. She was involved in completely restructuring and digitalising the warehouse storage, which included introducing a modern SAP system.

Thanks to the perfect interlocking of the various processes, the METRANS Dyko Rail Repair Shop is able to check and repair approximately 1,050 wagons and 600 locomotives per year. And of course also thanks to dedicated and flexible employees like Marcela Brantová.

Published 09/2022

Curious about us?

They have a lot to say – from the port, from the past, from their day-to-day work or from abroad.

Read more