Quicklinks

Quicklinks

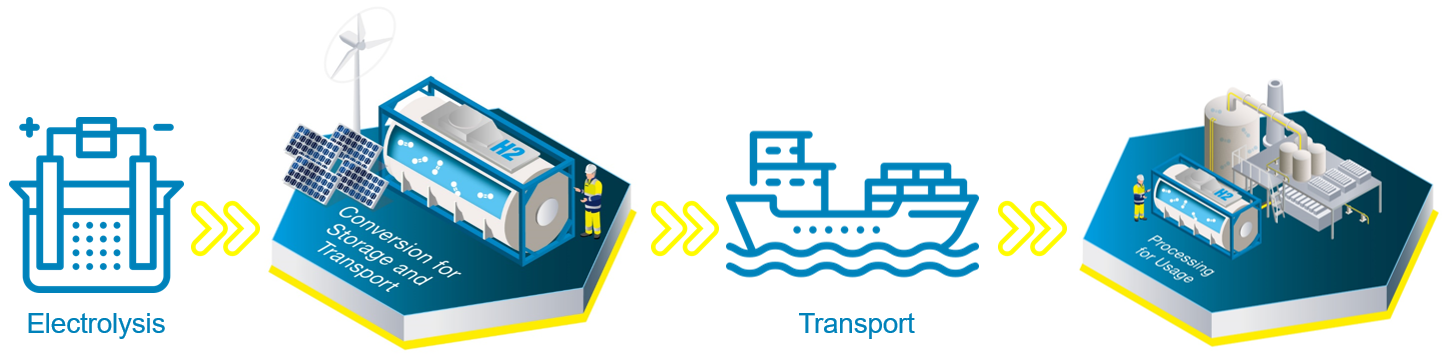

Similar to fossil fuels, hydrogen is not available everywhere as a renewable energy source. Transport options are required to make the energy source of the future accessible to industry worldwide.

HHLA sees hydrogen transport as an opportunity for our company to tap into a new business area. Different hydrogen transport options with compressed hydrogen, liquid hydrogen, ammonia, methanol and LOHC can play a role.

After hydrogen electrolysis, i.e. the splitting of water (H2O) into hydrogen (H2) and oxygen (O2), the hydrogen is present in a gaseous aggregate state. The problem with this form of hydrogen is that its volumetric energy density is very low.

The volumetric energy density of a substance is a measure of the energy content per unit of volume. For hydrogen at normal conditions (0°C and at atmospheric pressure), this means that one cubic metre filled with gaseous hydrogen contains about the same amount of energy as a water glass filled with diesel. When transporting energy sources like hydrogen, one wants to transport as much energy as possible in the smallest possible space, since this drastically reduces the necessary transport volume and thus the costs.

Various hydrogen transport options have been developed to achieve the goal of transporting as much energy as possible in the smallest possible space. With these transport options, the hydrogen is often transported not in its purely gaseous state but is converted into a liquid.

In collaboration with our partners, we are promoting the decarbonisation of handling and transport processes. Clean Port & Logistics , an innovation cluster to test hydrogen-powered port logistics equipment, aims to help with this.

Hydrogen is needed in its gaseous form for various processes in the metalworking industry, in refineries and in the chemicals industry, and it has been used for decades. To meet this need, hydrogen is currently manufactured with the help of a fossil fuel-powered steam reformer on-site and introduced to the process as a gas. For smaller applications and in research, compressed gas is transported by truck and stored in compressed gas tanks. The compression of gaseous hydrogen takes place after production and compresses the hydrogen to up to 700 bar, thus increasing its volumetric energy density. Since this hydrogen transport option is state of the art, an infrastructure already exists; however, it would have to be expanded to meet the increasing demand for hydrogen in the course of decarbonisation.

Moreover, the high pressures place increased demands on the material so that compressed hydrogen must be transported in thick-walled, heavy containers. This makes the transport of large volumes over long distances with mobile means of transport like trucks, trains and ships more expensive than other transport options.

The use of pipelines is conceivable because a pipeline’s high throughput and low variable costs make the hydrogen’s low energy density less pertinent, and it is unnecessary to compress the hydrogen strongly to 700 bar. Gaseous hydrogen is highly flammable.

With the liquid hydrogen transport option, the liquid hydrogen is transported without a carrier. The gas is cooled to -253°C and condensed to liquefy it. This process is established industrially and also takes place for other gases on a technical scale (for instance, for LNG). The use of liquid hydrogen is also established in other fields such as space travel.

Because the liquefaction takes place at such low temperatures, both the process and the transport are expensive and complex. If the temperature rises above -252 °C, the hydrogen gasifies and expands. In such a case, the storage tank would explode from the increasing internal pressure if it didn’t have safety valves to release the gaseous hydrogen into the outside air. Because it is unavoidable that part of the liquid hydrogen will gasify and must be released, loss-free storage for long periods is hardly possible.

Ammonia is a chemical compound consisting of hydrogen and nitrogen and is gaseous at room temperature. It is one of the most-produced chemicals in the world and is a basic material in industrial chemistry. Up to 150 million tonnes of ammonia produced are used annually, for instance in the manufacture of fertilisers. Accordingly, infrastructure is already in place, and experience has been made with the transport and storage of ammonia.

The versatile options for ammonia use present certain advantages. In some cases, green ammonia can simply be used as ammonia and can thus decarbonise part of the chemical industry. No processes must be converted – instead, a switch is simply made from natural gas-based ammonia to sustainably produced ammonia. If the hydrogen bonded in ammonia is needed (rather than the chemical per se), the chemical can be split into nitrogen and hydrogen in an endothermic ammonia-cracking process. This process is very energy-intensive and is still being researched. Due to the diverse areas of application and the established use of ammonia as a chemical, investment in market development is less risky.

The disadvantages lie in the material properties of ammonia, which is both flammable and toxic. Ammonia is also corrosive and thus places heavier demands on the storage material. The cracking process can also produce toxic nitrogen oxides.

Methanol is a chemical compound of hydrogen, carbon and oxygen (CH3OH). Chemically speaking, it is the simplest alcohol. Methanol is one of the most-produced organic chemicals and is a base ingredient for a number of chemical processes. It is used as an energy carrier in the manufacture of fuels and as a fuel in fuel cells.

At room temperature, methanol is a liquid and slightly volatile. Currently, most of the methanol produced annually (up to around 60 million tonnes) is made from synthesis gas, which in turn is produced by the steam reformation of natural gas (methane). There are two options to make this climate-damaging process more sustainable: either green methane must be produced by something like a biogas plant, or a CO2 point source must be available. A CO2 point source is usually an industrial facility that has high carbon emissions (such as a cement plant). This CO2 can then be captured as part of methanol production rather than released into the atmosphere.

Another disadvantage of methanol as a carrier of hydrogen is its high flammability and toxicity – though infrastructure is in place for its transport and storage, and people have experience with it. As with ammonia as a transport option, methanol can also be used as a fuel in fuel cells, as a chemical and for hydrogen storage. Again, the variety of application areas make investing in the market development of menthol less risky for HHLA.

LOHC stands for liquid organic hydrogen carriers, which are organic carriers to which hydrogen is chemically bound during hydrogenation. This creates heat, which can be used for heating spaces like residential buildings. Dehydrogenation in turn requires a great deal of heat; therefore, a prime location for a dehydrogenation facility is near a heat source that provides energy conveniently and inexpensively (such as an incineration facility, steelworks or a chemical plant). Alternatively, the required heat could be generated using green electricity, which is comparatively expensive.

The advantages of transporting hydrogen with LOHCs lie mainly in their low flammability, their transport at normal pressures and temperatures, and in the existing transport and storage infrastructure of fossil fuels like petroleum and diesel (tanks, tanker trucks, pipelines and pumps can be used for LOHC transport).

Disadvantages include, for one thing, the reverse logistics of the LOHC, since one must imagine the LOHC to be like a returnable bottle. After dehydrogenation, the empty container must be returned to the hydrogenation site. Another disadvantage is the high amount of energy required to make the hydrogen usable again. LOHCs are similar to petroleum in that they are classified as hazardous to water and health.

| Electrolysis | Conversion | Transport | Preparation for use | |

| Liquid hydrogen | Hydrogen is released from water by adding electricity | Liquefaction at -253°C | Cryogenic tank or chemical tanker | Gasification at temperatures above -252°C |

| Compressed hydrogen | Hydrogen is released from water by adding electricity | Compression at 700 bar | Gas canisters, pipeline and compressed gas trailer | No preparation necessary |

| Liquid organic hydrogen carriers (LOHC) | Hydrogen is released from water by adding electricity | Hydrogen is bound to LOHC as a carrier | Tank container or chemical tanker at normal temperature and pressure | Release of hydrogen from LOHC |

| Ammonia | Hydrogen is released from water by adding electricity | Production of ammonia from nitrogen and hydrogen and liquefaction | Tank container or chemical tanker at minus 33 degrees and pressurised | Hydrogen is split from nitrogen through cracking, or ammonia is used directly as a raw material |

| Methanol | Hydrogen is released from water by adding electricity | Production of methanol from carbon and hydrogen | Tank container or special ship at normal temperature and pressure | Methanol reformed to hydrogen and CO2 or used directly as raw material |

In order to achieve global climate goals, the use of hydrogen and thus the demand for hydrogen will increase. Accordingly, the requirements for the transport and storage volume of hydrogen will increase. Because the hydrogen strategy of the Federal Republic of Germany provides for most of the hydrogen to be imported, Hamburg and we at HHLA can play a key role in the future hydrogen economy.

The market for hydrogen is still very new and none of the transport options for importing hydrogen that were introduced here have yet been implemented on a large scale. An investment in this market phase would make hydrogen available earlier and in larger volumes, and thus create incentives in industry to implement climate-neutral processes based on green hydrogen. Since the transport options entail various infrastructure and transport requirements, investment in the construction of a hydrogen infrastructure is not without economic risk. However, in order to achieve global climate goals, investments in a hydrogen infrastructure must be made as quickly as possible.

International standards are required to generate planning security and make investments less risky. We at HHLA are driving forward the industrial testing of various transport options in its own projects, and is also a charter member of a foundation that aims to simplify the market ramp-up of hydrogen in Germany.

More information about hydrogen at HHLA

It is our aspiration to combine ecological, social and economic interests in order to make our company future-proof. We underline this with our "Balanced Logistics" sustainability strategy.

Read more