The HHLA Subsidiaries

Together with our subsidiaries, we at HHLA form a strong network that offers versatile and innovative solutions along the entire logistics chain. The expertise of our subsidiaries ranges from handling and transport services to consulting and developing terminals or venture building. Sustainability is a particular focus. By combining environmentally friendly transport solutions, efficient transport routes and intelligent technologies, we drive sustainable innovation in every area of logistics.

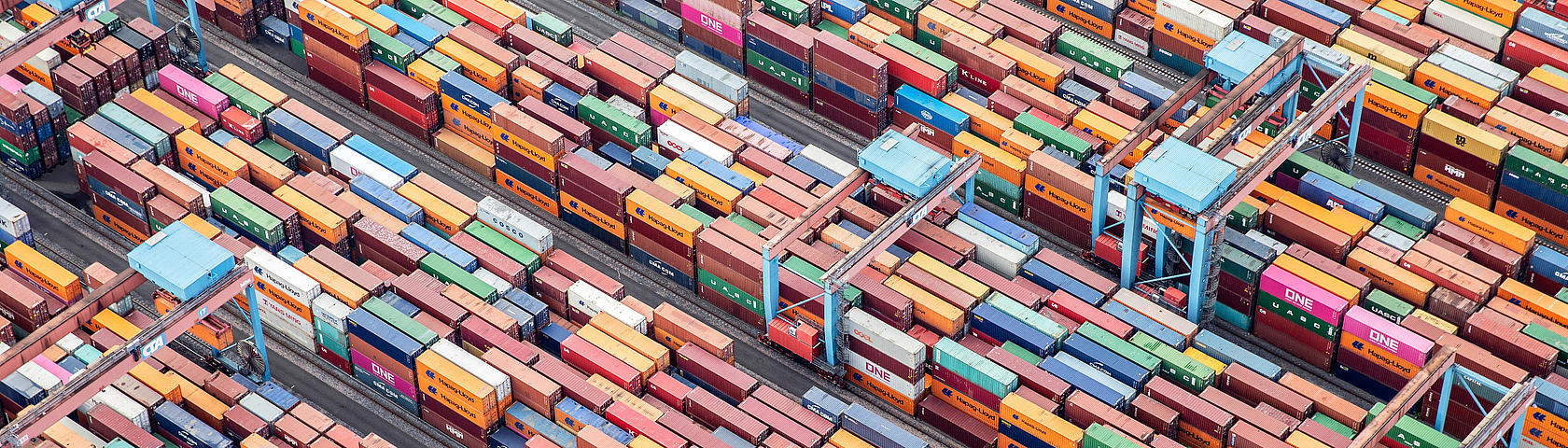

Seaport Terminals

Our seaward container and multi-function terminals in Hamburg, Tallinn, Trieste and Odessa are high-performance logistics hubs for global trade. They are complemented by specialised terminal facilities for general cargo, project cargo, RoRo, fruit handling and bulk goods.

Intermodal Transport

Whether by ship, rail or road, we rely on efficient and sustainable transport solutions to connect Europe's ports with the inland areas. By seamlessly combining different transport routes in our intermodal HHLA network, we offer flexible and environmentally friendly logistics concepts that reliably deliver goods to their destination.

Terminal-related Specialists

Our terminal-based specialists ensure that everything runs smoothly in and around our terminals in the Port of Hamburg. They hold the technology on site ready for use, coordinate the arrival and departure of ships, or take on the inspection, repair and cleaning of containers. With their expertise, our specialists are a crucial part of the smooth running of logistics at our terminals.

Start-ups and Innovation

Our innovation unit and its start-ups develop pioneering solutions that are shaping the future of logistics. With their expertise in automation, the development of state-of-the-art drone and control centre technology, or the development of new business areas through venture building, they are driving the digitalisation of the industry.

Consulting and Development

Our subsidiaries in the fields of consulting and development offer support worldwide in optimising logistics processes and the strategic development of maritime infrastructure. They are also responsible for expanding our HHLA network of international terminals, and ensure that our facilities work together optimally and are developed with the future in mind.

Real Estate

Project development, neighbourhood management and an appealing cityscape are among the core competencies of our real estate division. In addition, a traditional fishing location on the banks of the Elbe in Hamburg is being preserved and embedded in an intelligent neighbourhood development for the high-quality food industry and the catering trade.

The Power of Networks

We connect places, companies and people – shaping the logistics of tomorrow. To achieve this, we build on intelligent solutions and the power of our networks.

Learn more