20.02.2025

Higher capacity, lower emissions: CTB expands its automated yard

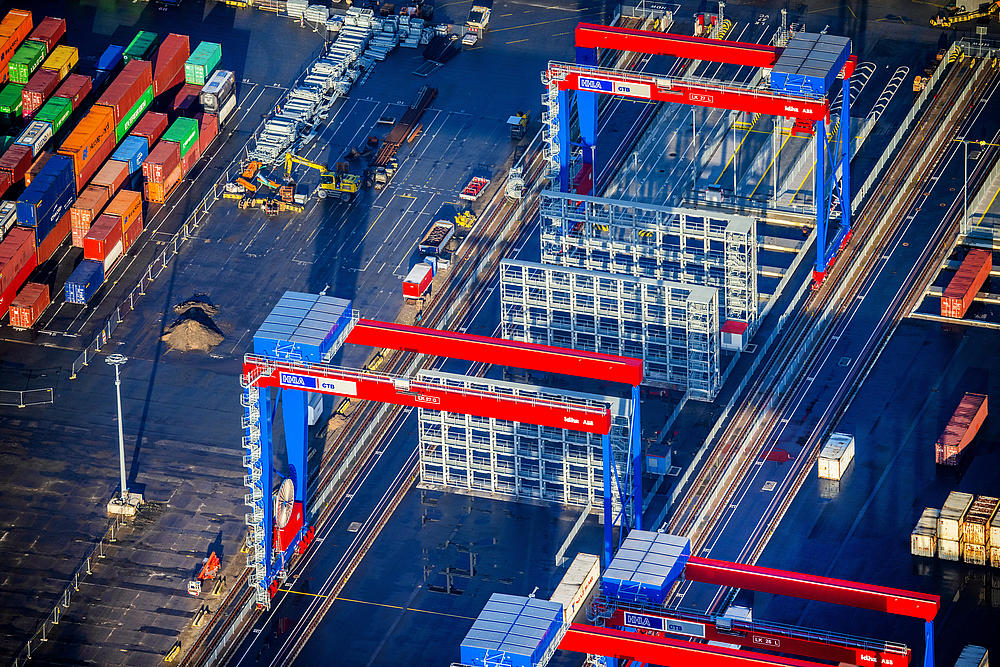

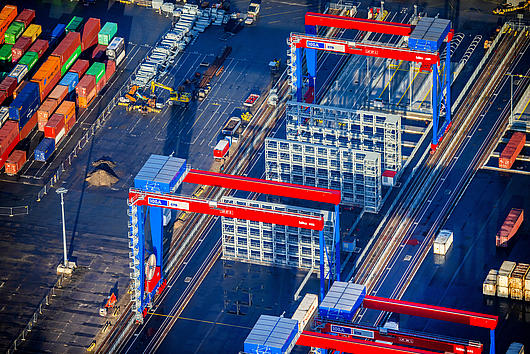

HHLA Container Terminal Burchardkai (CTB) in Hamburg is steadily pursuing its path towards automation and sustainability. In recent months, three additional cutting-edge storage blocks have successfully gone into operation. This means that there are now a total of 22 electric storage blocks in use at CTB, making an important contribution to the sustainable development of the terminal.

Since the end of 2024, the three new storage blocks have been gradually integrated into the terminal operations. They are expanding the existing block storage capacity by around 6,000 standard containers (TEU) to almost 45,000 TEU. Thanks to denser storage in the automated storage blocks, the space required is less than half compared to conventional straddle carrier yards.

The new storage blocks adjoin the northern side of the existing automated container yard and are each served by three electrically powered portal cranes. These will be supplied exclusively with electricity from renewable sources and will help to reduce CO2 emissions. This makes a major contribution towards HHLA’s goal of becoming climate-neutral throughout the Group by 2040.

Ingo Witte, CTB Managing Director: “With the three new storage blocks, we are steadily pursuing the modernisation of our terminal. The innovative systems offer a more efficient use of space, reduce emissions and optimise operations for our clients. In doing so, we are not only making CTB more efficient, we are also taking a significant step towards achieving our sustainability targets.”

The comprehensive modernisation of the biggest container terminal in Germany is seen as one of the most ambitious brownfield projects in the industry. In addition to the expansion of the automated block storage, the implementation of Automated Guided Vehicles (AGVs) for container handling at the mega-ship berths during normal operations is also a particular focus. As an automated container hub, CTB is a key element in the infrastructure of the Port of Hamburg and the European HHLA network.

How storage crane systems work:

The automated container store at CTB consists of storage blocks that are each 42 metres wide and 375 metres long and arranged side by side, with a capacity between 1,980 and 2,130 TEU depending on their type. One particular feature of CTB is the innovative yard crane system, which comprises three portal cranes that can drive over each other. This unique technology significantly boosts productivity by optimising crane control and moving around more efficiently.

The storage crane systems’ high-performance IT system is seamlessly integrated into the terminal’s overall control system and has been supported by a specially developed AI module for several years. This AI helps find optimal storage locations for the stored containers, keeping energy-intensive restacking processes to a minimum. This intelligent management makes processes more efficient and protects resources, which signifies another step towards more sustainable port logistics.

Download image

New environmentally friendly storage blocks at HHLA Container Terminal Burchardkai