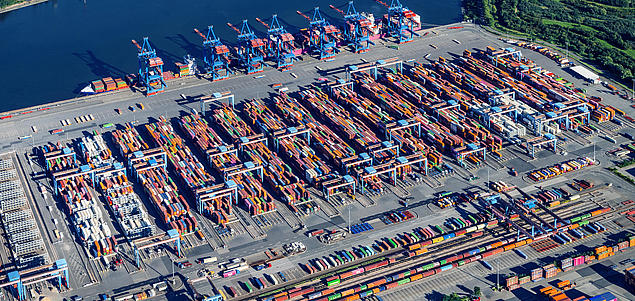

CTA Hamburg: Our HHLA Container Terminal Altenwerder

The HHLA Container Terminal Altenwerder (CTA) in Hamburg is one of the most modern and efficient seaport terminals in the world. Built in 2002 as a greenfield project on previously undeveloped land along a tributary of the Elbe, the Köhlbrand, it now plays a crucial role in ensuring smooth goods flows across Europe.

CTA Hamburg stands out for its high level of automation and pioneering sustainability concept. Cutting-edge technologies and innovative IT systems optimise port operations while reducing environmental impact. As a result, the HHLA Container Terminal Altenwerder is a global leader in efficiency and sustainability in cargo handling - a place where machine precision meets human excellence.

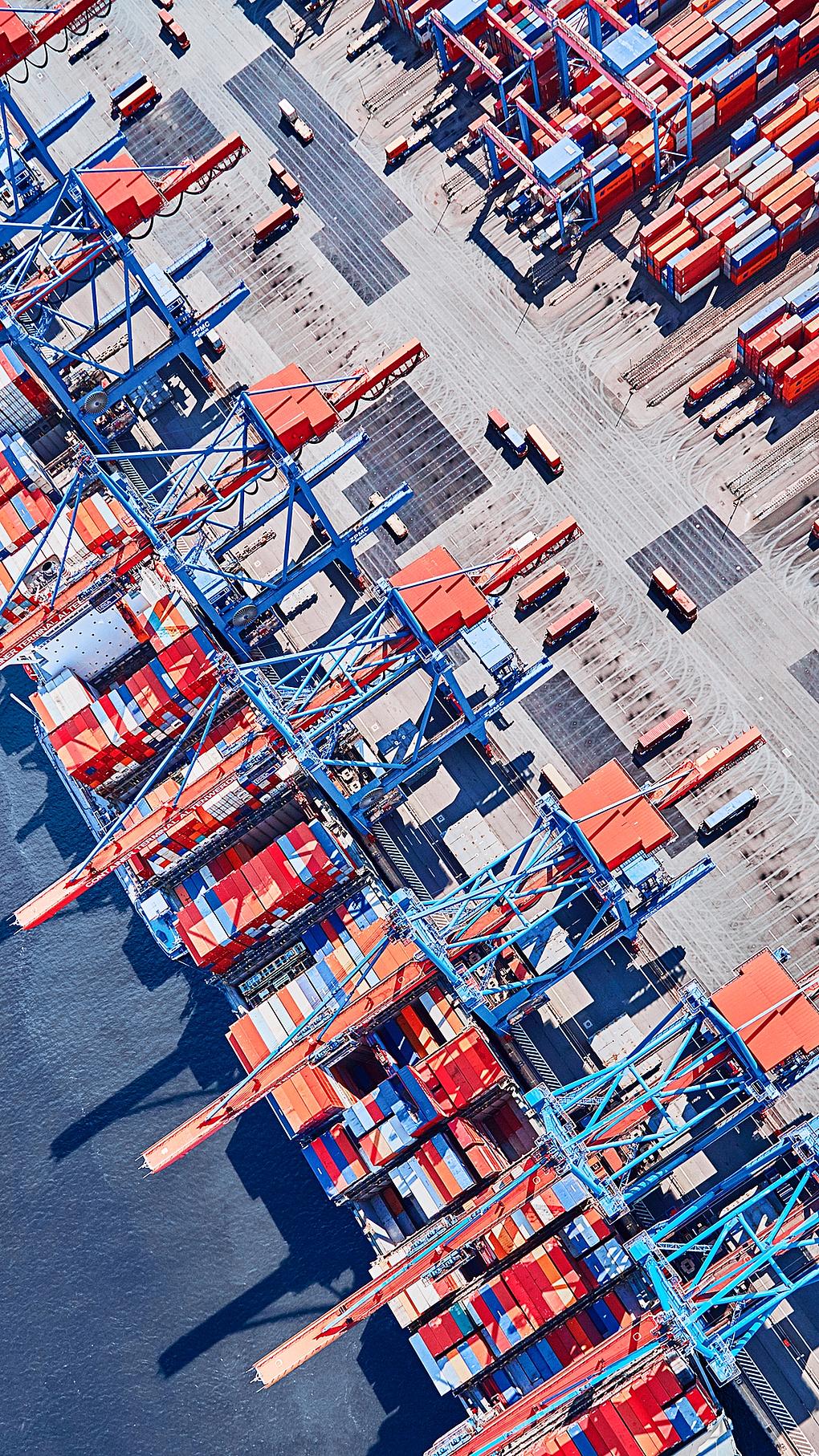

CTA Hamburg is a pioneer in port logistics automation. It leverages state-of-the-art technologies and innovative IT systems to ensure efficient and precise loading and unloading of seagoing vessels. Key examples of the terminal’s high level of automation include our driverless container transporters (AGVs), optical character recognition (OCR) gates, and the software-controlled gantry crane system.

However, automation at CTA is not about replacing people with machines: "Computers cannot solve problems. Humans are more efficient in unusual situations. With their experience, they can apply knowledge in new contexts and make decisions beyond programmable routines", emphasises Bernd Mann, CEO of HHLA subsidiary iSAM AG.

Automation in Logistics

With state-of-the-art technology, we optimise container handling, increase efficiency, and enhance safety at our terminals.

Read more

Our Container Terminal Altenwerder is a key player in Hamburg, Europe’s third-largest container port. Every day, thousands of containers move from road or rail onto ships. A fleet of 95 fully automated, battery-powered transport vehicles (Automated Guided Vehicles – AGVs) ensures smooth cargo movement between the container gantry cranes and the block storage area.

A specially developed software system determines the fastest route using more than 17,000 transponders embedded in the ground, which precisely track the vehicles’ positions. Another unique feature: these heavy-duty transporters autonomously recharge their batteries at dedicated charging stations.

The gates at HHLA Container Terminal Altenwerder use Optical Character Recognition (OCR) to identify all containers arriving by truck and rail. Seven cameras capture the necessary codes and document the condition of each container.

How OCR Optimises Terminal Processes:

- Reduced Transit Times for Trucks: Automatic vehicle and container recognition enables faster entry and exit, reducing truck transit times and increasing efficiency across the entire logistics value chain.

- Shorter Processing Times: OCR simplifies truck processing within the terminal, streamlining operations.

- Elimination of Gate Queues: Automating the entry and exit process prevents congestion at the gates.

- Enhanced Customer Service: A fully automated gate system ensures smooth operations, improving customer satisfaction.

- More Stable Logistics Processes: OCR technology minimises reliance on manual intervention, contributing to more reliable and efficient logistics operations.

The container storage area at CTA consists of 26 storage blocks, each managed by two rail-mounted gantry cranes (RMGs) of different heights. Their design allows the smaller crane to move beneath the larger one, enabling parallel operations.

Another key advantage: if one crane fails, the other continues operations, ensuring uninterrupted workflow. The software-controlled block storage system allows for the efficient storage of approximately 20,000 TEU within a compact footprint. This high space efficiency is a fundamental part of the terminal’s sustainable overall concept.

The Kombi-Transeuropa Terminal Hamburg (KTH) is the rail terminal at Container Terminal Altenwerder and the largest container rail terminal in Europe. It features nine tracks, each 720 meters long, designed to handle full-length freight trains.

An advanced train gate equipped with OCR technology automatically records container numbers as trains enter and transfers the data to the IT system. On the terminal grounds, four gantry cranes with rotating trolleys load and unload containers from trains—handling an impressive volume of approximately 900,000 standard containers (TEU) per year.

This makes CTA not only Germany’s largest rail terminal but also the biggest container rail terminal in Europe.

At CTA, specialised software enables us to sort and store containers with exceptional efficiency and precision. It also manages the AGVs that transport containers between the container gantry cranes and the block storage area.

Key functions of the control software at CTA:

- Ensuring a smooth and efficient container handling process

- Optimising AGV routes and minimising transport times

- Controlling the positioning of the container gantry cranes and the storage crane system to ensure fast and safe loading and unloading of seagoing vessels

- Monitoring the condition of the equipment and reporting any malfunctions

CTA Hamburg in Figures

Sustainability is a core concern for us at HHLA. With our sustainability strategy, “Balanced Logistics”, we aim to unite ecological, social, and economic interests. Our goal is to reduce CO₂ emissions by at least 50 percent by 2030 and achieve emission-free operations by 2040.

By converting the entire AGV fleet to battery-electric propulsion, the CTA saves around three million litres of diesel annually, which corresponds to approximately 8,000 tonnes of CO2 emissions – a significant step for HHLA towards a more sustainable and emission-free port operation.

Furthermore, the integration of the batteries into the electricity market demonstrates the innovative potential of this technology: The AGV batteries can be used to provide primary control power to the electricity grid. Surplus energy from the grid is stored in the batteries or fed back into the grid when needed to help stabilise the grid frequency.

Gantry Cranes

All 14 container gantry cranes for waterside handling are powered by green electricity.Storage Crane System

The 52 gantry cranes in the container block storage are powered by green electricity.Rail Gantry Cranes

The four rail gantry cranes are also powered by green electricity.Hamburg's rail port is the second-largest in the world, handling a volume equivalent to the combined rail freight of Rotterdam, Antwerp, Bremerhaven, and Wilhelmshaven. Nearly every second hinterland container arrives or departs from the Port of Hamburg by rail. Short distances at CTA Hamburg and excellent rail connections ensure that our goods are transported ever more efficiently and sustainably in a global market with highly complex supply chains.

FAQ – Frequently Asked Questions about CTA Hamburg

What is CTA and where is it located?

Our HHLA Container Terminal Altenwerder (CTA) is one of the most modern and efficient container terminals in the world. It is located in the Port of Hamburg, at the Köhlbrand, a tributary of the Elbe River.

How does the HHLA Container Terminal Altenwerder operate?

The CTA is a highly automated terminal. Driverless transport vehicles (AGVs) move the containers between the quay cranes, the container yard, and the railway station. Software-controlled gantry cranes sort the containers in the block storage area.

What are the special features of CTA Hamburg?

In addition to its high degree of automation, the reduction of CO2 emissions is a key feature of the Container Terminal Altenwerder. Large equipment is powered by green electricity, transport vehicles are battery-electric, and emit no pollutants.

What impact does automation have on employment at the CTA?

For us, automation means creating optimal collaboration between humans and machines. We place great emphasis on developing the skills and qualifications of our employees to prepare them for new challenges. Our processes, workflows, and applications are designed to ensure seamless interaction between humans and machines - enabling flexible and intelligent logistics.

The Power of Networks

We connect places, companies and people – shaping the logistics of tomorrow. To achieve this, we build on intelligent solutions and the power of our networks.

Learn more