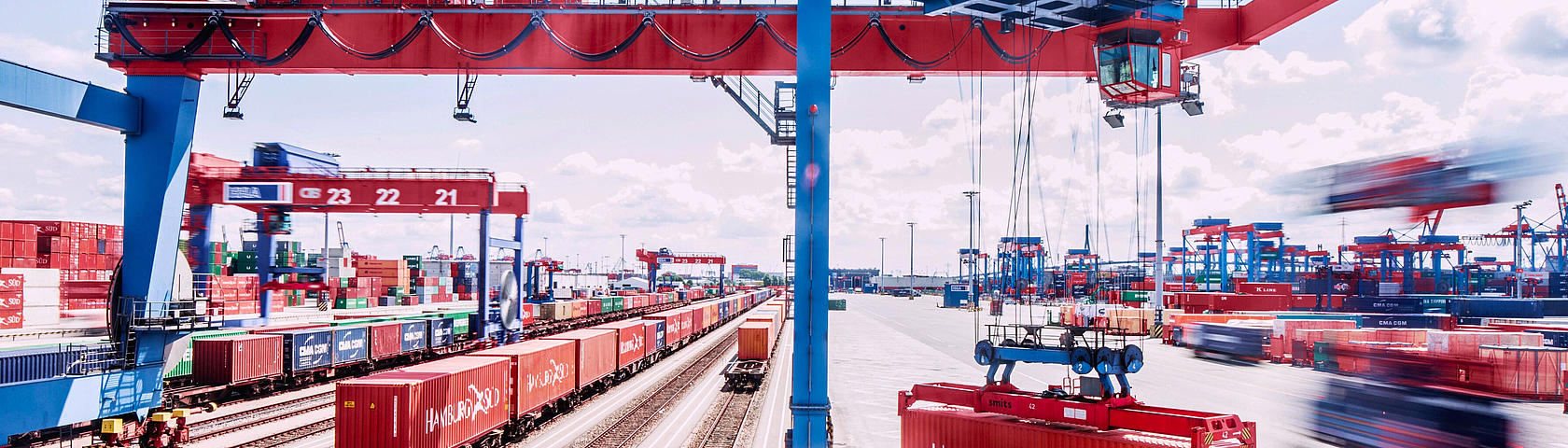

Hamburg Railway Port: Europe's frontrunner

The Port of Hamburg is not only one of the largest seaports in the world, but also the largest railway port in Europe. More than half of all hinterland containers reach or leave the port via environmentally friendly rail. This figure underlines the immense importance of rail for freight transport in and around Hamburg and makes the Hanseatic city an indispensable hub for climate-friendly European logistics chains and our HHLA logistics network.

The Port of Hamburg is increasingly focusing on environmentally friendly rail freight transport to reduce CO2 emissions. Modern and highly automated terminals such as our HHLA Container Terminals Altenwerder (CTA) and Burchardkai (CTB) ensure efficient transhipment between ship and rail. This enables us to offer our customers a reliable and environmentally conscious solution for the transport of their goods.

When it comes to container transport by rail, Germany's largest seaport is the undisputed leader. Around half of all containers arrive at or depart from the port by rail. This makes Hamburg the largest railway port in Europe and the second largest in the world.

In a direct comparison, more goods are transported by rail in the Port of Hamburg than in the ports of Rotterdam and Antwerp combined. This outstanding position underlines the efficiency of Hamburg's rail port. For our customers, this means a reliable and efficient solution for their international logistics requirements.

Facts and Figures on Rail Freight Transport

In Hamburg, rail accounts for a significantly larger share of hinterland transport than trucks:

- In 2024, the Hamburg port railway transported almost 46 million tonnes of goods and 2.6 million TEU.

- Around 200 freight trains arrive at or depart from the port every working day. These trains transport not only containers, but also bulk goods such as iron ore and coal for steelworks and potash for the chemical industry.

- New cars and various general cargo also use the railways as an indispensable link to the hinterland.

- Containers transported by rail cover significantly longer distances than those transported by road.

Intermodal Logistics

Whether by ship, rail or road: we use our logistics hubs to provide a wide range of solutions for intermodal freight transport.

Learn moreEcological Advantages of Rail Freight Transport

The Port of Hamburg makes optimal use of the combination of environmentally friendly modes of transport: rail and large ships. Rail freight transport offers considerable ecological advantages over road transport:

- Converted to tonne-kilometres, a train emits 110 times less CO2 than a truck.

- In addition, railways require only 1.2 hectares of land per kilometre of track, while road freight transport requires 3.6 hectares – three times as much.

This optimisation of land use and emissions is an important step towards more sustainable logistics.

HHLA Container Terminals and METRANS Network

All of our HHLA terminals in the Port of Hamburg have state-of-the-art, high-performance freight terminals, offering excellent conditions for the efficient handling of containers and goods. The container terminals at CTA (Container Terminal Altenwerder) and CTB (Burchardkai) are among the largest and most modern of their kind in Europe. With around 900,000 TEU containers handled annually, the terminal at our Altenwerder container terminal is the largest container terminal in Europe.

Our HHLA rail subsidiary METRANS complements our offering with an extensive and efficient rail network for rail freight transport. Regular connections, operated almost entirely with electric locomotives, make an important contribution to reducing CO2 emissions while enabling a high degree of flexibility and scalability in the logistics chain.

Our customers benefit from optimal connections to the European rail network and the ability to transport their goods using one of the most environmentally friendly and economical modes of transport.

Infrastructure of the Hamburg Port Railway

The Hamburg Port Railway, operated by the Hamburg Port Authority (HPA), is the central link between Hamburg's seaport terminals and the European rail network:

- A rail network of around 290 kilometres with approximately 750 points ensures the efficient handling of daily rail traffic.

- Around 210 freight trains with more than 5,500 wagons travel here every day.

- This public network is supplemented by around 80 sidings with a further 120 kilometres of track owned by industrial, transhipment and logistics companies.

A modern, IT-supported operating system ensures that rail traffic is precisely timed and that all trains arrive at their destinations reliably and on time. The Alte Süderelbe port railway station, with its striking tower, coordinates rail operations between European destinations and the large container terminals in the western port area.

Hamburg's Railway Port Sets Track For The Future

The Hamburg railway port forms the backbone of European logistics and sets standards in climate-friendly freight transport. With its efficient infrastructure, high transhipment volume and numerous national and international connections, it is a central hub in our European logistics network.

For companies seeking to make their supply chains sustainable and future-proof, our HHLA terminals in the Port of Hamburg offer the ideal combination of modern infrastructure, an efficient network and many years of experience in rail freight transport.

Together with our customers, we are setting the course for green and efficient logistics. At HHLA, we are continuously working to further optimise our customers' logistics processes, both ecologically and economically.

What is the significance of Hamburg's railway port?

The Port of Hamburg is Europe's largest railway port and the second largest worldwide. Almost every second rail container arrives at or leaves the port by rail. In direct comparison, more goods are transported by rail in the Port of Hamburg than in the ports of Rotterdam and Antwerp combined.

How many train connections are available in the Port of Hamburg?

The Hamburg Port Railway has a 290-kilometre rail network with around 750 points and over 160 licensed railway companies (EVUs). Around 210 freight trains with more than 5,500 wagons run every day. No other port offers as many rail connections within Germany and Europe as Hamburg.

What are the advantages of rail freight transport in the Port of Hamburg?

From an ecological perspective, rail freight transport is particularly advantageous. Compared to trucks, trains emit 110 times less CO2 per tonne-kilometre and require only 1.2 hectares of space per kilometre travelled, compared to 3.6 hectares for road freight transport. Rail is ideal for long distances and the transport of large quantities, thus contributing to more efficient and environmentally friendly logistics chains.

The Power of Networks

We connect places, companies and people – shaping the logistics of tomorrow. To achieve this, we build on intelligent solutions and the power of our networks.

Learn more