Instead of diesel fumes, trains may soon just be emitting steam into the air. However, it won’t come from traditional steam engines but from hydrogen fuel cells. The world’s first scheduled service is now operating using this technology in Bremervörde, northern Germany. The HHLA magazine took a closer look at the clean rail transport of the future.

Christian Glauner’s passenger train slowly trundles along the tracks at Bremervörde station. The journey to the other end of the Elbe-Weser-Verkehrsbetriebe (EVB) site takes the train past a “rail bus” from the 1950s, which serves tourists on the “Moorexpress” line. “There's an impressive juxtaposition of history within a few metres here,” grins Glauner, Team Leader for EVB’s traction units.

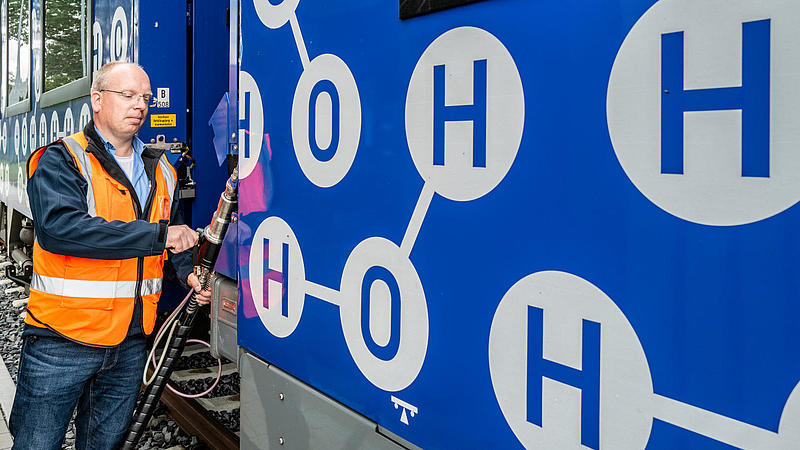

His train is literally moving towards the future. The head driver wants to refuel the traction unit – not with diesel, as has previously been the case, but with hydrogen. The blue, white and yellow vehicle is an Alstom Coradia iLINT, where the abbreviation stands for Leichter Innovativer Nahverkehrstriebwagen (light innovative local transport traction unit). The lower-case i makes the difference: Instead of diesel engines, this latest addition to the EVB fleet is powered by an electric motor that is powered by electricity from hydrogen fuel cells.

Global pioneer in the use of hydrogen

14 of these vehicles will be travelling on EVB’s tracks between Bremerhaven, Cuxhaven and Buxtehude. The final models are currently being delivered – the world’s first hydrogen trains for regular use. This climate-friendly, green model will now set the precedent: EVB, train manufacturer Alstom and the Smart Mobility Institute Bremerhaven are working with other partners on running hydrogen-powered shunters in the Port of Hamburg.

Hydrogen as a fuel source for locomotives? It’s a new and pioneering concept. The gaseous element, also known as H2, is seen by many as the fuel of the future. It is obtained from water through the process of electrolysis. If renewable energy sources are used to obtain it, we call it "green" hydrogen. Inside the fuel cell, it reacts with oxygen again. This releases electrical energy – the only emission is water vapour and a little condensate.

“It’s as clean as a whistle,” Christian Glauner summarises. The only thing is that green hydrogen is not yet available in sufficient quantities. “Until then, we are operating our trains using what is known as grey hydrogen," explains Tilmann Rös, Deputy Manager of EVB’s Rail Vehicle Technology division.

Producing green hydrogen for your own use soon

The gas is a by-product of a chemicals plant in Stade and is delivered to Bremervörde in special containers. This interim solution is not expected to be needed for much longer. EVB wants to build its own wind farm and install an electrolyser right next to the refuelling point. “We want to be producing our own green hydrogen in about three years’ time,” Rös emphasises.

Why is EVB switching over to hydrogen already then? With its passenger and goods trains, public transport buses and coaches, the company founded in 1907 is one of the biggest transport service providers in the Elbe-Weser area. As a logistics company, EVB is active throughout Germany.

The “home straight” of the 235-kilometre EVB rail network, the RB 33 from Cuxhaven to Bremerhaven, Bremervörde and Buxtehude, was not deemed a viable candidate for electrification. The Landesnahverkehrsgesellschaft Niedersachsen (Lower Saxony Local Transport Association, LNVG) started to look for alternatives for these kinds of lines and set a course for the future in 2014: Together with the train manufacturer Alstom, EVB started to garner its initial experiences with two hydrogen-powered trains, developed in Germany, in day-to-day scheduled services for two years starting in 2018.

Hydrogen trains replace the last diesel locomotives

The project was a success: It resulted in the previous diesel traction units being replaced by hydrogen-powered engines in summer 2022. To start with, 14 clean traction units will be using the EVB tracks and it is highly likely that other regions will follow this example. “In order to do even more to protect the climate, we will not be buying any more diesel vehicles,” assures Carmen Schwabl, spokeswoman for the LNVG management. LNVG owns all of the local transport trains in Lower Saxony, including 126 diesel-powered traction units.

Train driver Glauner has now stopped his train at the refuelling point. Right next to the track is a kind of control cabinet with a card reader, monitor and two pressure hoses with a diameter about the same as that of a garden hosepipe. The refuelling process is almost identical to the process used at an LPG refuelling station for gas-powered cars, for example.

First, Glauner identifies himself with a refuelling card, then he connects the end of one of the two high-pressure hoses to the train’s fuel nozzle and locks it into position – the refuelling point takes care of everything else. Sensors monitor that everything works properly. Hydrogen is no more dangerous than any other fuel – even if it were to leak out of a faulty seal, it would dissipate quickly: “Hydrogen is lighter than air,” the train driver says.

Hydrogen as a future opportunity

At HHLA, we want to become climate-neutral by 2040 as part of our sustainability strategy. As an energy source, hydrogen will make a significant contribution to this.

Read moreWith its hydrogen filling station, EVB has already passed a major milestone on the journey towards carbon-neutral rail transport. The system was constructed as a prototype by the gas producer and engineering company Linde. With a storage capacity of 1,800 kg hydrogen, it is one of the biggest filling stations of its kind in the world. Normally, hydrogen is stored in large, domed tanks. For EVB and Alstom, Linde replaced these large spheres with 64 tube-shaped constant pressure tanks that compress the hydrogen to a pressure of 500 bar with the aid of hydraulic props. The filling station is able to discharge approximately 1,600 kg of hydrogen to the trains within 24 hours.

Not dangerous when refueling: hydrogen

Each traction unit has two tanks, each able to hold 130 kg, which are mounted on the roof – along with the two fuel cells – for safety reasons. If there were to be a leak, the hydrogen would simply dissipate upwards because, as mentioned above, hydrogen is lighter than air.

The fuel cells with an output of 200 kW each continually provide electricity, which is stored in batteries and discharged to the two electric motors, each with an output of 272 kW. “We use around 26 kilograms of hydrogen per 100 kilometres,” the train driver says. He proudly points to a bright red badge on his train: “This train has travelled a total of 1,175 km without refuelling, thus setting a world record.”

The EVB trains can’t come close to this record. They have to refuel way before they reach the 1,000 km mark. The refuelling process takes just 15 minutes: “Right, off we go again!,” Glauner exclaims.

Fuel cells for shunters?

EVB goods locomotives and trains also regularly trundle through the Port of Hamburg. Whether or not the hydrogen technology is also suitable for goods transport is something that is currently being researched by the Smart Mobility Institute Bremerhaven. In the medium term, shunters may be equipped with fuel cells and electric motors. The joint research project sH2unter sees EVB and Alstom collaborating with other partners to research the requirements of such shunters.

The challenge is in the high, fast-changing engine power that the shunters have to be able to provide. As a result of the requirements of shunting, these powerful workhorses cannot obtain their energy from overhead cables or batteries with electrical energy. “In light of this, hydrogen technology is of particular significance for shunting,” the project partners believe. HHLA’s rail subsidiary Metrans also sees its greatest potential in shunting in particular.

The foundations are scheduled to be laid by the end of May 2024 and the hydrogen-powered shunter should have completed its first test drives. In terms of passenger transport, hydrogen trains have been an everyday sight in the Elbe-Weser triangle for a while now – even if the passengers are not actually aware of it. “You can only spot it thanks to one detail. The new trains are much, much quieter than the diesel traction units thanks to their fuel cells and electric motors,” Glauner says.