Why were AGVs needed?

In the long history of port technology, automated guided vehicles (AGVs) are one of the most recent inventions. As increasing numbers of container ships started arriving in the ports, specialist cranes now known as container gantry cranes were constructed with a jib that could be lowered over the ship. Straddle carriers were developed in the late 1960s for the horizontal transportation of containers between the quayside and the container store. The history of the long-legged specialist vehicle with a hoist that made it possible to lift containers practically right “under its belly” as it were is told here.

As with any invention, this also had its disadvantages in addition to the relatively high purchase price. Above all, larger areas were now required for storing the containers because a lane of around 1.5 metres in width now had to be left between the individual rows of containers. However, the final inspiration for the development of a new category of container transporters came from another technical innovation. Since the 1970s, rubber-tyred gantry cranes (RTGs) and rail-mounted gantry cranes (RMGs) had been in use at container yards. They were able to stack containers right next to each other, with stack heights of up to six containers.

The crane thinks for itself

What defines modern container yards? It saves a lot of space, employs AI and is powered by green electricity.

Read moreWhat precursors inspired the first AGV?

The need was growing for a simple yet reliable vehicle for transporting heavy loads which no longer had to lift or stack them itself. One source of inspiration were the driverless transportation systems for the internal transportation of materials that had been in use in production and warehouse logistics since the early 1980s. They were known as AGVs, and container terminal operators were able to see their potential.

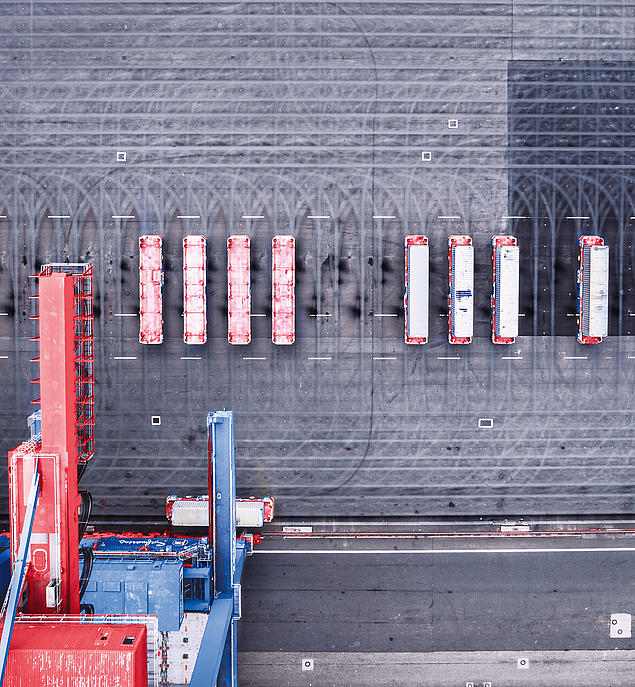

By 1993, the first fleet of 58 AGVs from German manufacturer Gottwald were operating at the ECT Delta Terminal in Rotterdam. Weighing approximately 14 tonnes, the boxy, flat transporters with no driver’s cab were able to accommodate two standard containers (20-foot or TEU) or one 40- or 45-foot container. They transported containers between the container gantry cranes and the yard cranes.

The transport orders were conveyed from a central terminal logistics management system to each individual AGV via radio. They had an on-board computer equipped with special AGV control software. This software basically took over the role of the driver, giving acceleration and steering commands to the AGV drive system. In return, the AGVs communicated their location, order status and other information relating to their operation to the terminal logistics management system.

To ensure that the AGVs on the terminal site were able to find their way reliably, two technologies were combined: the AGVs had an antenna that was able to identify the RFID transponders submerged every 2 metres in a grid formation in the terminal floor. The transponder locations, which were measured using extreme precision, were used as anchor points. The AGV travelled the distances between the transponders using an inertial navigation system based on the vehicle acceleration values.

What was the background behind the development in Hamburg?

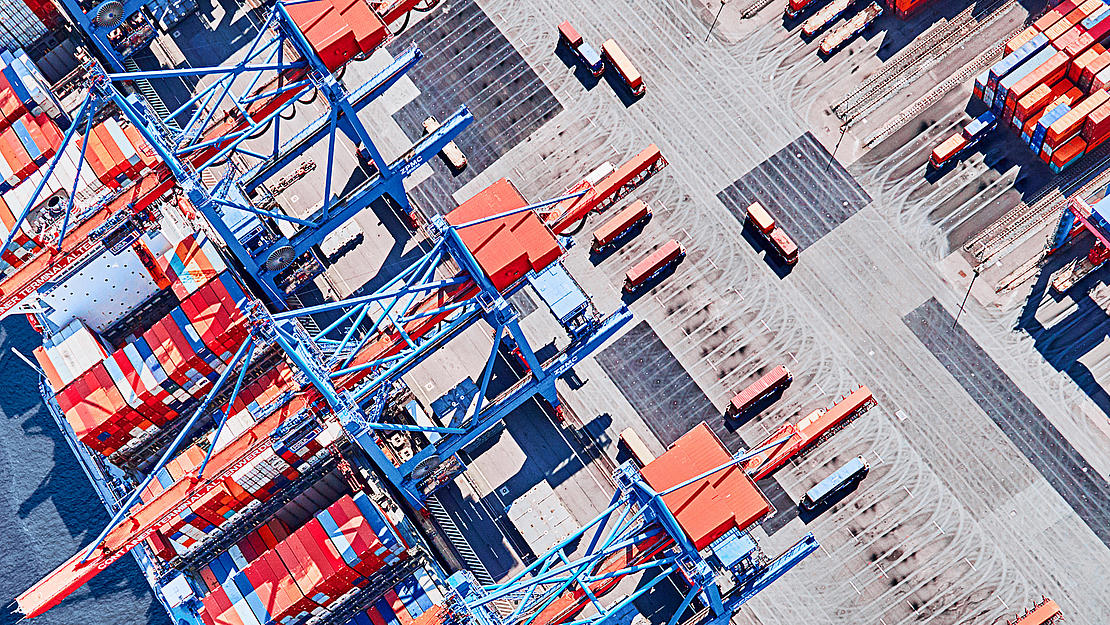

In 2002, the underlying AGV technology in the Port of Hamburg at HHLA Container Terminal Altenwerder (CTA) was embraced and improved. The combination of dual-trolley container gantry cranes at the quayside with the onshore rail-mounted yard cranes resulted in a unique operating concept. The path a container takes from the gantry trolley on the container gantry crane to its retrieval by the yard crane is largely automated and does not require the physical presence of a member of the terminal staff.

In order to make this terminal concept a reality, an IT system was developed in-house for controlling and monitoring the cranes, the AGV fleet, the yard and other major areas of the terminal. The decision to develop our own IT system was made because at that time there were no standard terminal operating systems (TOS) available that fulfilled CTA’s requirements.

The innovative combination of dual-trolley container gantry cranes, AGVs and rail-mounted gantry cranes (RMGs) that can be operated one above the other together with the necessary data connection with protagonists in and around the Port of Hamburg required an IT system tailored to CTA’s requirements. It made it possible to control the AGVs flexibly, among other things. Transponders integrated into the terminal floor enabled a suitable route to be found and optimised in real time. Since CTA went into operation over 20 years ago, the software and handling and transportation equipment has been continually upgraded and/or replaced. As a result, the highly automated terminal operating concept is still one of the most cutting-edge of its kind in the world.

AGVs are now considered state-of-the-art in terms of container handling. Globally, there are now around 15 container terminals using AGV in China, the Netherlands, Singapore, Japan, Germany and the USA. They are located on what are known as greenfield sites, i.e. recently constructed terminals, such as CTA. There are very few brownfield projects, i.e. existing sites that have been repurposed. This is where HHLA in Hamburg is once again a true pioneer with its Container Terminal Burchardkai (CTB).

A lot of staying power

Hamburg's Burchardkai is being redeveloped. What does a project manager do in the largest brownfield project of its kind in Europe's ports?

Read the portraitCan AGVs be powered by renewable energy?

While the basic principle behind AGV navigation has remained largely unchanged, there has been a revolution in terms of their drive technologies to make them more sustainable. The first examples at CTA used diesel-powered hydraulic systems. With this type of drive system, the mechanical energy from the diesel engine was transferred to the AGV drive systems via the force of oil pressure. These were followed by the more efficient diesel-electric vehicles, where the energy from the diesel engine was converted into electricity by a generator in order to power the AGV.

Then, the need for sustainable heavy goods transport resulted in battery-powered AGVs coming onto the market. They no longer generated the electricity they required from diesel but charged their batteries with green electricity (completely from renewable sources at HHLA in Hamburg).The entire AGV fleet at CTA, comprising around 100 vehicles, has now switched over to green energy.

The battery-powered AGVs no longer emit any pollutants, and are much quieter and easier to maintain than their diesel-powered predecessors. There are various concepts with regard to handling their battery charging cycles in order to avoid AGV downtime. For example, batteries can be exchanged at a battery swapping station. This process is automated at modern AGV terminals (such as in Rotterdam and Long Beach).

CTA, however, opted for the concept of integrating several fast-charging stations along the AGV routes. In low-throughput phases, the AGVs drive to these charging points and recharge their batteries. Occasional charging works in a similar way. Here, the battery is charged when the AGV is waiting for the crane in the yard’s pick-up position. This makes best use of unproductive waiting times in order to increase the overall amount of time the AGV can be used.

What do the experts conclude?

After 30 years of experience with AGVs, the conclusions are positive. The biggest advantage of AGV-based horizontal transportation compared with the manned systems (straddle carriers and tractor units with a chassis) was their significantly higher processing efficiency. This not only applies to the handling of the vehicle but also to the organisation of work in the port. Unscheduled downtime due to absences or shift changes are no longer a problem.

Driverless vehicles are generally very safe and no serious accidents involving AGVs have been recorded. Finally, the operating costs are lower than for manned transportation systems. No drivers are required to operate them and the requirements of the electric drive technology in terms of maintenance and replacement parts are much lower than for diesel-electric straddle carriers, for example. These clear advantages are countered by increased costs for setting up a terminal IT system that is tailored to the operational processes in place. Added to this are infrastructure costs for integrating a transponder grid in the vehicle lanes.

Overall, the trend towards increased automation is continuing in the port. As a result, we can expect to see an increase in the number of terminals using AGV-based transportation systems. In addition to the proven partnership between AGVs and rail-mounted yard cranes, AGVs can also be used in conjunction with the innovative BOXBAY high-bay warehousing system.

In the future, it may be possible for driverless AGVs to share their operating area with manned vehicles. Onshore, they could handle the transportation between the container store and the rail terminal and could be used to approach trucks from outside the terminal. To do this, standard localisation and navigation methods such as LiDAR (light detection and ranging) sensor fusion, camera systems and satellite navigation (GSSN or GPS) will need to be developed and tested in addition to transponder-based navigation. The findings from this process will likely accelerate the switch to AGV transportation in other existing container terminals.

Our guest author Dipl.-Wi.-Ing. Johann Bergmann is the team leader for Port Technologies in the Hamburg Fraunhofer Center for Maritime Logistics and Services CML and one of the world's best-informed experts on AGV.