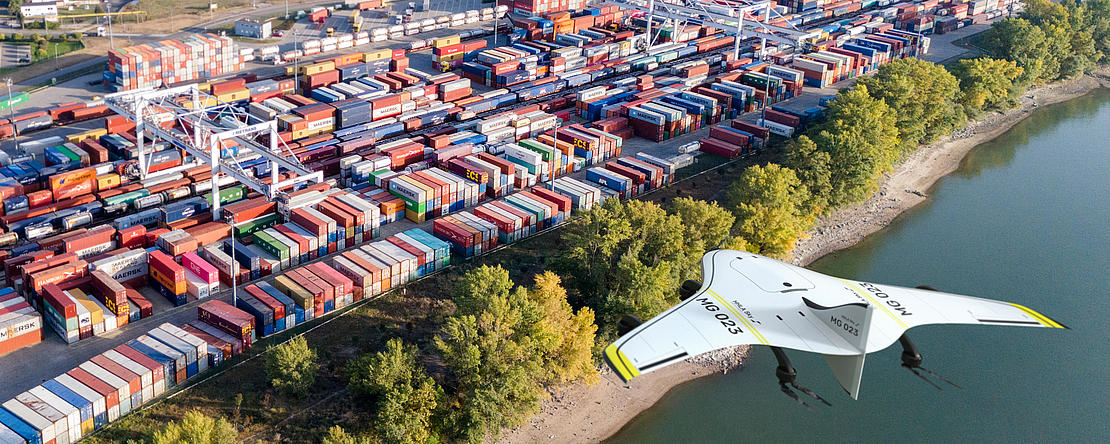

The controlled use of professional drones over industrial plants and commercial areas places high demands on hardware and software. As a leading provider, HHLA Sky has developed both the control centre for monitoring flights and the drones themselves in-house. “Security, reliability and utility are the basis of our technologies,” says Managing Director Matthias Gronstedt.

With its Integrated Control Center and a carefully curated portfolio of industrial drones, HHLA Sky has introduced to the market a sophisticated system with a unique selling proposition.The Control Center can be used to monitor more than 100 drone missions simultaneously over very long distances. “In our view, drones must always be part of an effectively designed automation solution,” says Gronstedt.

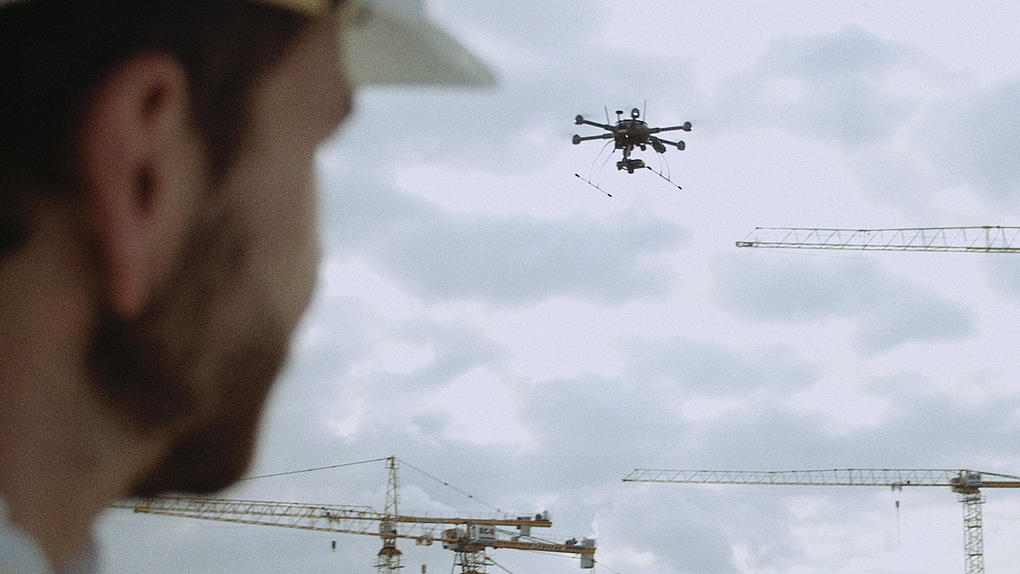

Drones make many jobs easier or enable new activities in the first place. They offer the perfect overview when monitoring construction sites, in agriculture, disaster relief or environmental protection. They can transport cargo, collect data quickly or keep people out of danger zones. “That said, efficiency is only achieved when I fully integrate drones and their tasks into industrial processes. Then I can request drones and have them fly automatically almost at the push of a button,” Gronstedt is convinced.

Entire process chains are automated

Such automation requires that the Control Center and the drones (or the mobile robots on the ground) are precisely coordinated with each other so that they can communicate with precision in fractions of a second. “That’s why we have closely integrated the development of all system components,” says Gronstedt. For this reason, HHLA Sky has automated not only the actual flying, but the entire process chain essential to drone operations on an industrial scale. “Our Integrated Control Center is software for control and process management. It manages everything – from planning routes and flight requests from other systems such as SAP, to flights, data transfer and drone maintenance,” says Gronstedt. “We have also incorporated mobile robots that can autonomously handle air cargo from the drone and transport this to the production hall. Each of these steps is monitored by humans who can intervene at any time.”

Drones for all purposes

Professional drones are fast, precise and are constantly opening up new areas of application. An overview of the variety of unmanned aerial vehicles.

Read moreFrom the experts' point of view, drones are simply flying robots. In addition, there are travelling, floating and even diving robots for use on the ground or for special missions on and in the water. The aim is to control all of these vehicles via a common control centre.

HHLA Sky's portfolio currently includes three flying multicopters, a fixed-wing aircraft and a mobile robot for use on the ground. All HHLA Sky products are safe in every respect and are even certified by TÜV with regard to cybersecurity. These drones and mobile robots were developed or are offered to customers by HHLA Sky: