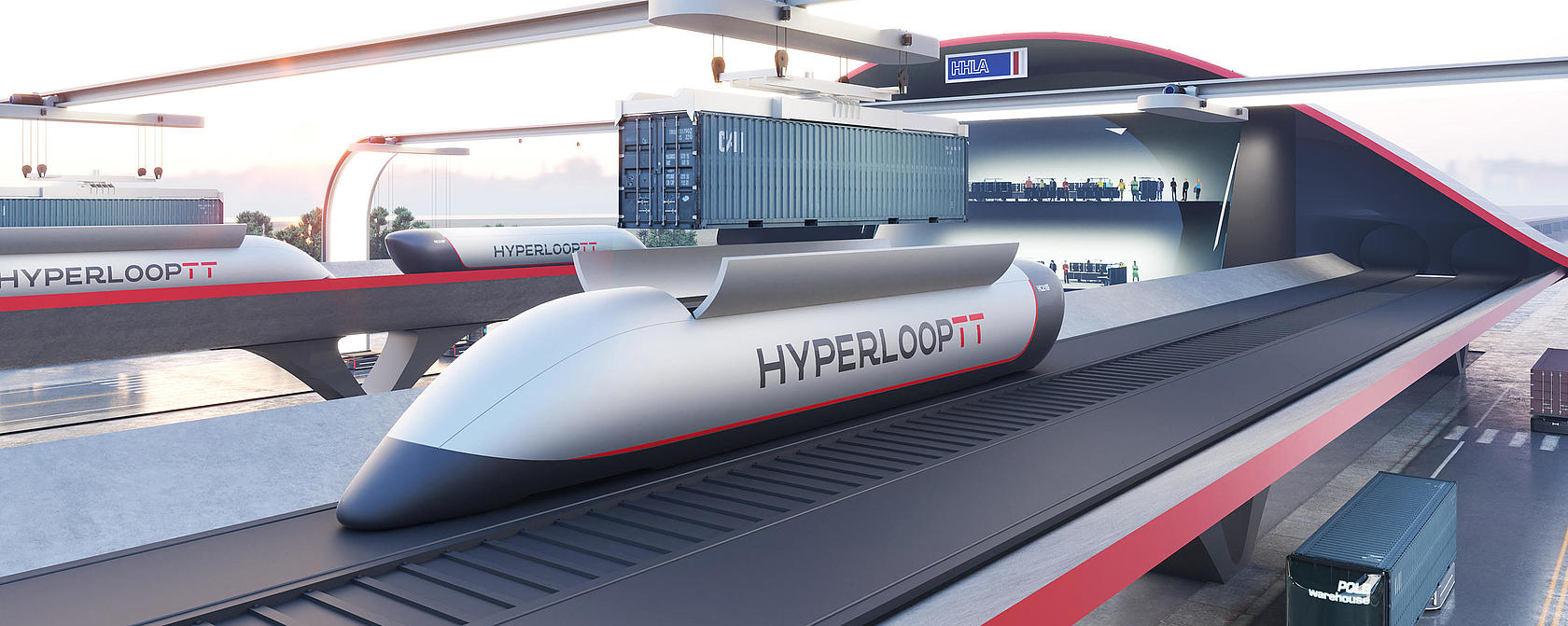

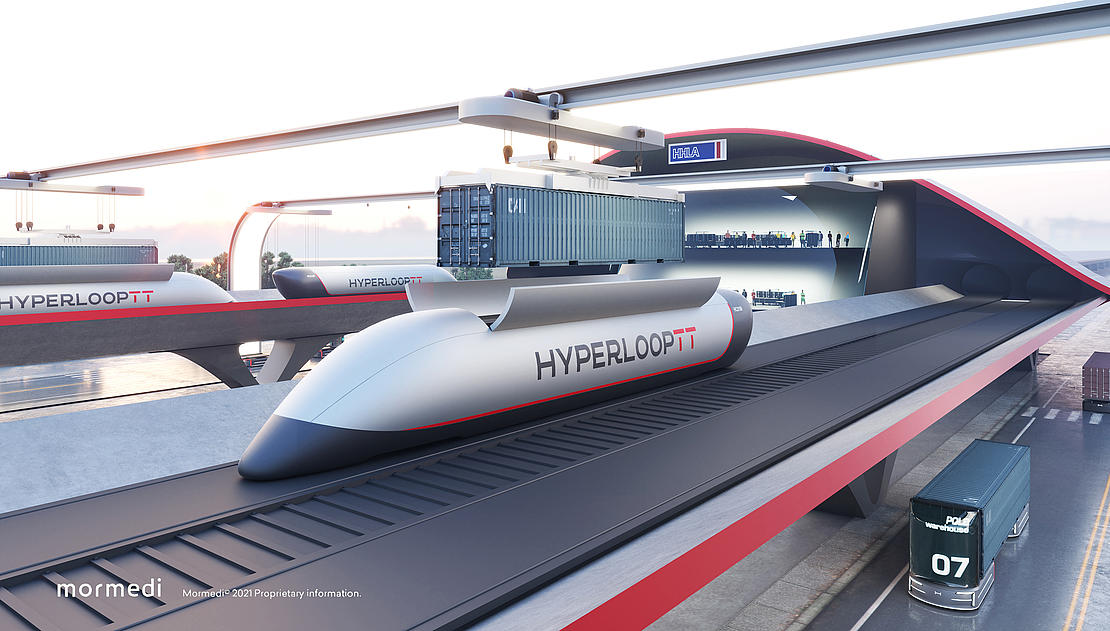

A vacuum tube; streamlined pods, each containing one or two containers; a magnetic system that causes the pods to hover: these are the ingredients that make up the Hyperloop, which may be the sustainable transport system of the future. Engineers and scientists throughout the world are working on realising this idea. Coupled with HHLA’s experience, this could result in a complete handling system, the “HyperPort”.

Could people or containers reach their goals faster than they do now by rail or truck? With his white paper on a “Hyperloop”, American entrepreneur Elon Musk provided an answer to this question in 2013. In the meantime, Musk has concentrated on even faster modes of transport with his company SpaceX, which builds rockets and spaceships. Yet experts in many disciplines around the globe are working to realise their vision of moving people or goods in special pods in nearly airless tubes via electromagnetic propulsion at 600 km/h.

The idea is ingenious. The basic framework is a system of tubes in which there is a virtual vacuum, meaning there is almost no aerodynamic drag on the transport pods that levitate in them. The pods run smoothly on a permanent magnetic field and are propelled by a “linear electric motor” which has no rotating parts. Electrical impulses travel between magnets from front to back, which creates the rapid propulsion.

Extremely low energy consumption

The air inside the tube is as thin as in the upper stratosphere – the pressure is one hectopascal (hPa). By way of comparison, on a nice summer day in Hamburg, the air pressure is between 1,020 and 1,030 hPa. In the magnetic field, there is no rolling resistance that brakes wheels like there is on the road or on rails; therefore, developers are convinced that very little energy is required.

Electrical energy powers a linear motor that accelerates the transport pod to its tremendous speed. Dutch engineers have calculated that no more power is needed to start a container in the Hyperloop than is required to turn on a light bulb. Should the transport pods be equipped with solar collectors as planned, the entire system will even be able to generate much more energy than it uses!

The idea of the Hyperloop has a long history. In 1825, the London and Edinburgh Vacuum Tunnel Company wanted to make vehicles travel on rails through vacuum tunnels in order to save energy. Now the utopia can become reality. Elon Musk called on the new generation of global scientists to promote the feasibility of the Hyperloop via his aerospace company SpaceX. A team from the Technical University of Munich is at the forefront of this endeavour. While the students built a reduced-scale tube and pod system that reached a speed of 482 km/h.

the American company Hyperloop Transport Technologies (Hyperloop TT) has connected 800 experts in a worldwide network. These efforts have made an idea into a system which is already being tested on a test track in Toulouse.

The HyperPort is expected to rapidly transport containers to the hinterland

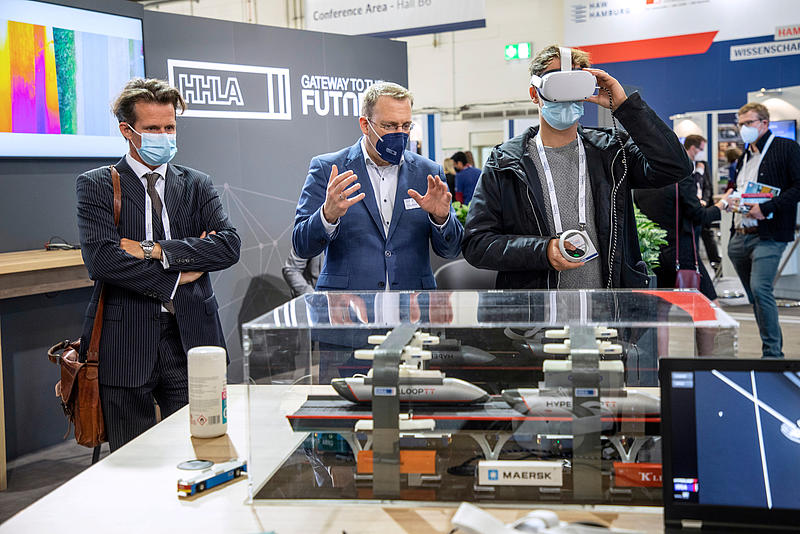

In 2018, HHLA and HyperloopTT established the HyperPort Cargo Solutions (HCS) joint venture, and they have been developing a joint concept for a container port since then. This HyperPort is expected to use the Hyperloop system to transport containers quickly between the hinterland and the port. Though this sounds a bit like science fiction, it isn’t – and to a certain extent, the partners have grounded their vision by developing a demonstrator that uses virtual reality to allow visitors to climb on board the train of the future.

Gerlinde John is heading the project for HHLA. She has already done pioneering work in the Port of Hamburg and played a key role in the development of the first extensively automated container terminal in Altenwerder (CTA). “Because innovation is a central theme for our company, we are involved in the concept for a ‘HyperPort’ as the port of the future,” she says.

The visionary

For more than 20 years, Gerlinde John has played a key role in driving forward the automation of the Port of Hamburg. Read the portrait of a pragmatic visionary.

A great deal of expertise is needed to realise the idea. At first glance, it would seem simple to move containers into or out of the port and to handle them at quayside. Yet knowledge and skill are needed for this to function smoothly. HHLA possesses both, and it is therefore the ideal partner for the HyperPort project.

While the principle of the HyperPort is relatively simple, it requires precise planning and the coordination of processes. In short cycle times, the containers are moved from the quayside or the yard on self-driving transport units to HyperPort loading stations and are loaded by cranes into the transport pods. Every 60 seconds, a pod takes off at high speed towards the recipient in the hinterland and back again – minus the traffic jams and carbon emissions. Self-driving vehicles are already deployed in terminal transport at Container Terminal Altenwerder (CTA) in Hamburg but are to be developed further for the HyperPort.

The HyperPort could represent the next milestone on the way to the future of container transport. Hyperloop TT has erected its first test centre with a vacuum tube and levitating pods in the French aerospace metropolis of Toulouse. Initial trials are to begin shortly. A feasibility study for the construction of a first Hyperloop route is under way in the Great Lakes region on the border between the US and Canada. The first commercial prototype for a passenger Hyperloop is expected to be created in Dubai. Private and public companies are also working together to construct a test track in the Netherlands.

The demonstrator, which was developed jointly by Hyperloop TT and HHLA, is an important link in the global chain of Hyperloop projects. It proves that integration of the visionary transport system is possible in an automated container terminal. “It does look very impressive,” says Gerlinde John with regard to the visualisation, which was displayed for the first time at the 2021 ITS World Congress in Hamburg. In the virtual model, visitors donned VR headsets to follow the container’s path from the ship to the Hyperloop. In doing so, they learned about the individual components of a HyperPort and could investigate the technical details of the transport pods.

Is Hamburg now becoming a HyperPort? Gerlinde John provides an open, honest answer to this question: “It will take a number of years before we know whether freight can ever be transported from point A to point B using such a system.” Only then will it be possible to consider specific applications. “First of all, engineers and developers are required,” the expert stresses.

HHLA must get involved with innovative technologies at the right time

There is a good reason why HHLA nonetheless got involved in a Hyperloop project at such an early stage: “If we want to strengthen and expand our role as one of Europe’s leading logistics companies, we must get involved with innovative technologies at the right time,” Gerlinde John emphasises. The site at which this kind of system will later be put into practice is irrelevant at the moment. “For us, what counts is not only the expertise we contribute to this development through our collaboration with Hyperloop TT, but also the expertise we gain for ourselves.”

This open approach to ideas that reach well into the future has a tradition with both HHLA and Gerlinde John. People at HHLA are used to hearing criticism about visionary projects in Germany. Two decades ago, plans for the automated container terminal in Altenwerder were greeted with just as much scepticism as the Hyperloop idea is today. The engineer recalls, “At the time, we were the first ones to realise such a project. Today, this kind of thing is standard in port handling.”

Perhaps one day the Hyperloop and the HyperPort will send a similar message. This vision incorporates more than just the idea of transporting up to 2,800 containers per day from point A to point B at 600 km/h. The Hyperloop is an interesting, if futuristic, approach to solving our current transportation system’s pressing challenges: rapid transport through a tube can make a substantial contribution towards relieving road congestion. In addition, considerably less energy would be required than with traditional transport by road and rail, and environmental pollution through CO2 emissions and noise would be reduced significantly.

Getting containers out of the port as quickly as possible is important for economic reasons for a handling company like HHLA. Gerlinde John says, “Such a system can increase handling and storage capacity.” Yet speed is not everything with this project. “A fast system like the Hyperloop has to be integrated perfectly into port operations,” as the expert knows from her experience with automating the CTA.