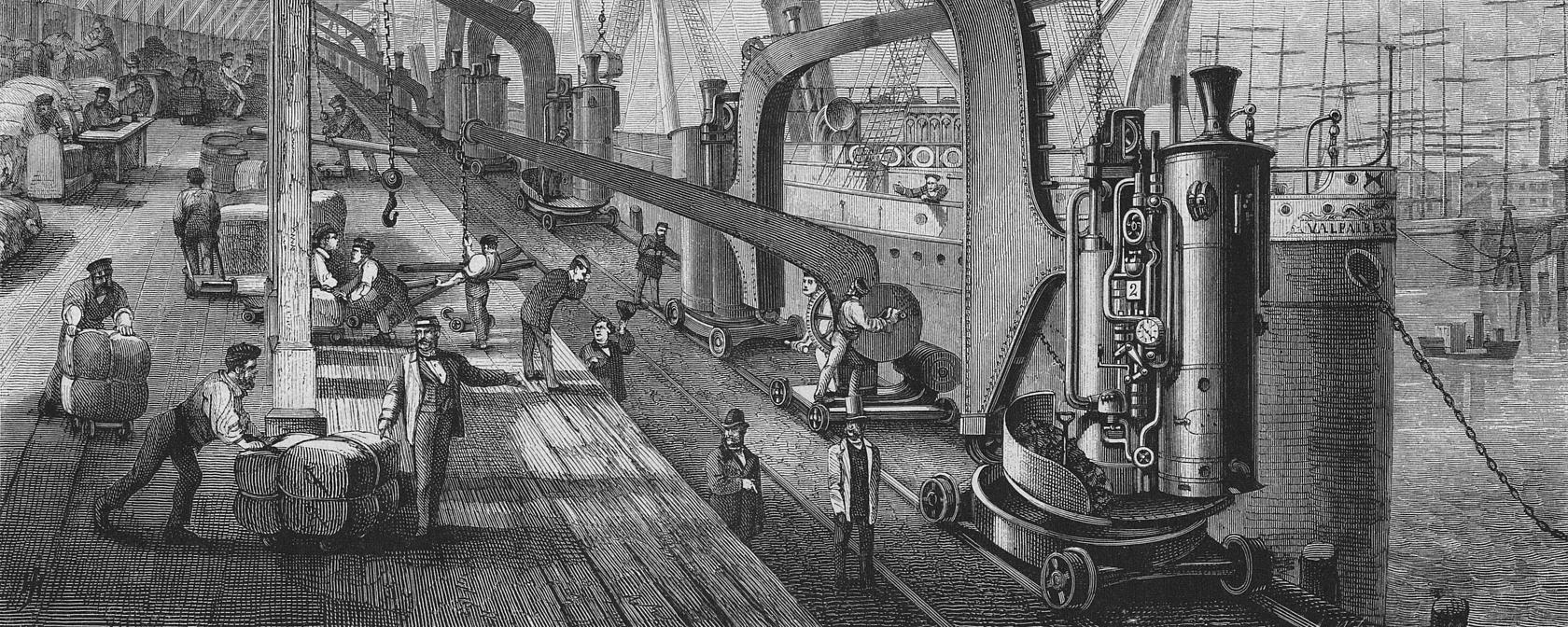

In the late nineteenth century, heavy loads were a job for strong muscles in the Port of Hamburg – or for Brown’s steam cranes (see picture above) which made handling easier with their lifting strength, for example at Sandthorkai, the most modern part of the Port of Hamburg. Even there, cargo was unloaded and towed under dim lighting at dark times of the day and of the year. Gas lanterns and oil lamps made fire an omnipresent danger in port and warehouse work.

Then, a light gradually started to shine on the people of Hamburg, first in 1888 in the newly opened Speicherstadt. As owner and builder, the HFLG (a predecessor of HHLA) relied on electric lighting from the very beginning in the most modern and largest port logistics centre of its time. Not only did it become brighter in the warehouse blocks, but the canals were also lit by carbon arc lamps.

The electrification of the port quickly spread: The first usable electric crane went into operation in 1891 at Petersenkai in Baakenhafen, marking the end of the less efficient steam cranes.

Swarming electric carts in the port

At that time, about 25,000 people were employed at the Port of Hamburg, half of them as dockers for loading and unloading ships. They moved hundreds of sack carts back and forth between quayside and storage sheds with their muscle power. To process a single ship, 200 to 500 people had to unload almost all break bulk with these primitive tools.

The electric cart was an innovative leap forward in goods handling. In 1925, an experiment supervised by the quay management showed that one electric cart driver could move 10,000 sacks of sugar as quickly as ten cart pushers. Soon, the port was swarming with the battery-powered (!!) transport vehicles.

The forklift combined two work levels

But stacking the sacks or crates was still dangerous and back-breaking work. Here, the first German forklift truck EGS 1000 or "Muli" from the Still company (see picture) brought the next big efficiency boost. It combined the working levels of a shed crane and an electric cart, namely vertical and horizontal. Kühne & Nagel used it for the first time in the south-west port from 1950, and HHLA also used forklifts from 1952. By the 1960s, they were in use on all quays.

Only a few years later, a simple invention made not only the new forklift look old but also the entire logistics of the storage sheds on the quay. It was a stackable tin box with standardised dimensions – the container that started a revolution in logistics.

Everything that came in boxes or bags also fit into the container

On 2 June 1968, the American Lancer of the United States Lines arrived as the first fully containerised ship in the Port of Hamburg. The best thing about the steel box? It meant warehouses all over the world could be modular and waterproof. Transhipment and onward transport by truck or rail are also simple and efficient due to their standard length of 20 or 40 feet.

Gradually, the container replaced first the storage sheds in the port and then the entire Speicherstadt. These days, only highly specialised businesses such as coffee roasters, tea and spice blenders, and the carpet trade still use this historic warehouse complex, which was once the world’s largest. Everything else that came in boxes or bags from overseas sooner or later found itself in the container. The container turned out to be the most powerful logistics invention of all time, surpassed only by the wheel and the ship itself.

However, in order to tailor the transport chains entirely to fit containers, the handling technology had to be completely redesigned. The metal container, which weighed tonnes, overwhelmed the forklift truck and the lifting capacity of many cranes. When the Burchardkai in Hamburg was developed into a berth for container ships, HHLA installed the first container gantry cranes and, in addition, a number of quay cranes with lifting capacities of up to 25 tonnes. The first straddle carriers, high-legged specialised transport vehicles with claws for containers, were developed in cooperation with HHLA and moved containers between ship and truck from 1968 onwards.

Port productivity gave the box wings

At Burchardkai, soon to be known as a “container terminal” or CTB, things were advancing fast. The first container ship coming from the Far East line moored in January 1972, and by the end of the 1970s, more than 100 lines from all over the world were bringing containers to Hamburg via the river Elbe. The Hanseatic City was integrated early and very successfully into the global network of steel box logistics.

Productivity at the port took flight. Coffee as an example: Approximately 24 tonnes of coffee beans fit into a modern standard container like the ones handled at CTB. That is only one tonne less than a quay worker moved during an entire shift in 1964. These days, a dock worker handles about 1,920 tonnes of coffee beans in the same amount of time – almost 80 times as much. Or for the connoisseurs: the raw material for almost 300 million cups of coffee.

Milestones in Port Logistics (2)

Mountains of paper become streams of data that control a terminal. The professions in the port are also changing rapidly.

Read more