Uhříněves is located at Prague’s south-eastern edge. Before it was swallowed up by the capital, it was a small Bohemian town with a church and train station. It was from here that the first goods train loaded with containers set off for the port city of Hamburg in February 1992. The operation was organised by Metrans, a newly established company with a big vision.

The idea of a regular container shuttle service came from Jiri Samek. The founder of Metrans, who left us far too soon, also inspired many other ideas, which highly-motivated employees integrated into his dynamic company. The first thing Metrans wanted to do was to link what was then Czechoslovakia with the seaport in Hamburg. As an inland port, it isn’t actually on the coast itself but has a very traditional trading route to Hamburg with inland waterway ships via the Vitava River and the Elbe River.

When the Iron Curtain fell, the formerly socialist countries started to import lots of new consumer and capital goods. For the most part, they were mainly transported on poorly maintained, clogged road networks. At the borders, trucks sometimes had to wait one or two days until they had been processed by customs. Rail transport was very hard to plan and not a viable option. That is, until Metrans started using the rail network for container trains. Their connections boasted impressive reliability, short transit times and high capacities. The frequency of their shuttle services continued to increase. Soon, they were handling a huge part of the imports and exports for the Czech Republic, which separated amicably from its neighbour Slovakia in late 1992.

With a new vision and extra services

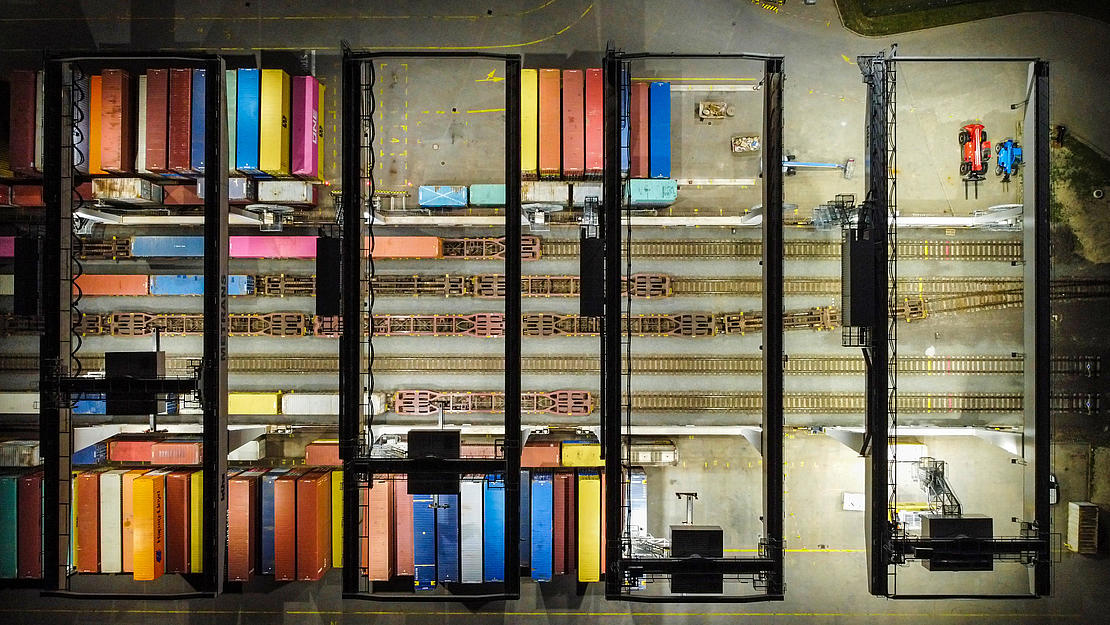

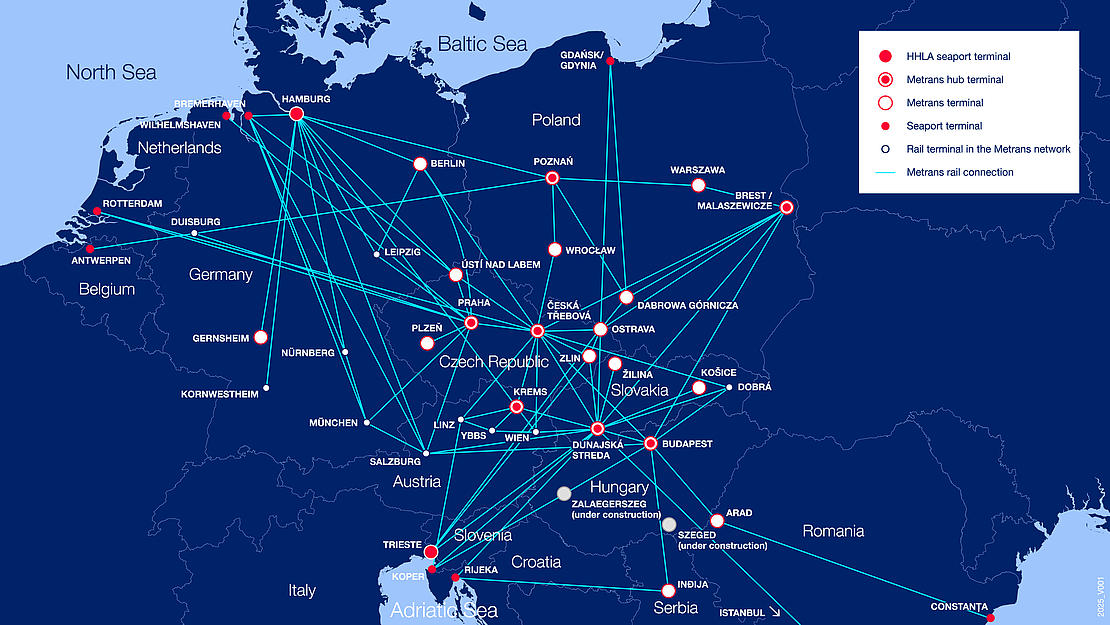

Three decades later, a huge container terminal in Uhříněves works for HHLA’s rail subsidiary Metrans, one of the main hubs in a network covering 20 European inland terminals. The six rail gantry cranes and 13 reach stackers can handle up to ten trains simultaneously. In the sustainably modernised office building, around 500 employees schedule the containers and try to handle all customer requests as straightforwardly as possible.

This is completely in the spirit of Jiri Samek, as his successor and Chairman of the Board Peter Kiss explains: “Our vision is one of comprehensive service and a flexible solution. We want to use this to help our customers in a whole range of situations. But if our customer wants it, we will also search for very specific solutions.“

Kiss joined the company in 1999, likewise inspired by Samek’s ideas for rail logistics. In the same year, intermodal transport underwent a revival in Slovakia before the country was linked up with Hungary. Lots more terminals followed, which were either constructed by the company itself, purchased or leased.

Network between four seas

The dynamic growth was also thanks to HHLA’s involvement from the mid-1990s. With it, capital expenditure quickly took on new dimensions although the fundamental principle behind Metrans remained the same. Containers are quickly moved away from the ports via frequent shuttle connections. In the hinterland, they are then sorted at the hub terminals before completing the final mile of their journey to the recipients on “antenna trains” and heavy goods vehicles.

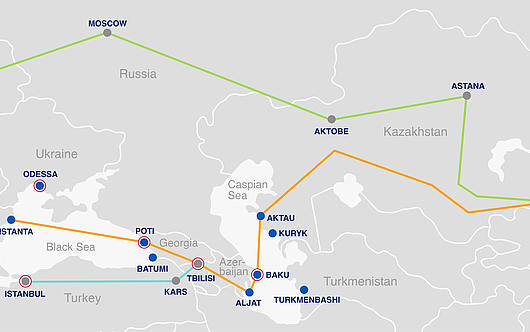

There is now a closely interwoven network of Metrans rail connections covering the whole area between the North Sea and the Adriatic, the Baltic and the Black Sea. Metrans is one of Europe’s leading private rail operators, with most container trains crossing one or more borders. As a result, this comes with numerous challenges.

What difficulties does this entail exactly? And how does the rail transport company Metrans handle them in day-to-day operations? At first glance, it all looks pretty simple: the block train with a capacity of 100 TEU is already loaded at the terminal – a long, brightly coloured procession of modern container wagons. At the front, the powerful electric locomotive has already been coupled up and the brake test for the unit has already been completed.

The train is ready to set off through Europe – from Rotterdam in the far west to Malszewicze far in the east, or from the northern seaports of Bremerhaven, Hamburg and Gdansk to Prague, Budapest and Krems, or onward even further to Trieste and Istanbul. The hubs, inland and port terminals of Metrans, HHLA and their partners are found at these locations and many more besides. Running between them is a highly efficient network of connections for rail freight.

The tricky part is dealing with the technical details of the systems

But day-to-day operations are not quite as straightforward as it might seem from Metrans’ network map. At least, the tracks themselves shouldn’t be a problem, should they? After all, the standardised rails with a gauge of 1,435 millimetres are used in most countries. Only, they don't go as far as Tallinn and Odessa, which still use the Russian gauge, and where HHLA also operates port terminals. But even disregarding this, difficulties arise from other details, too.

“Europe has a range of different electricity systems for powering locomotives, as well as varying control and signalling systems that we have to adjust to.”

These differences in energy technology have developed over time. Depending on the country, power is supplied either as alternating current with a voltage of 15 kV and a frequency of 16.7 hertz (as in Germany) or 25 kV/50 Hz, or as direct current systems with 1,500 or 3,000 volts. The result: to this day, many railway companies change their locomotives at internal EU borders because they are only suitable for the traction current of one country.

This slows operations and causes delays in the heavily loaded network. Border crossings between Germany and the Czech Republic are also affected, though long freight trains could easily be using the organisational possibilities that the Schengen zone provides by eliminating border checks between member states. Also read the following interview:

“We need European thinking for rail transport!”

Josef Doppelbauer, Director of the EU Agency for Railways, talks about long-term goals and current obstacles.

Learn moreMetrans shows how it can work from a technical perspective. “Our multi-system Bombardier and Siemens locomotives are equipped to deal with the power supply as well as the control and signalling systems of numerous countries,” Martin Horinek is pleased to relate. As Chief Operating Officer of the Metrans Group, he is the Executive Board member responsible for operations as well as the Managing Director of freight traffic at Metrans Rail.

Company-owned locomotives and specially developed wagons

All 80 mainline locomotives are equipped to accommodate Germany, Austria, Poland, the Czech Republic, Slovakia and Hungary as standard. A further 13 vehicles can also be used in the Netherlands and another 15 locomotives can be used in Slovenia and Romania. “These kinds of all-rounders are of course more expensive than basic locomotives. But for Metrans, the investment is well worth it because it means we can offer fast, reliable connections across various borders”, Horinek explains.

In addition to its own locomotives, Metrans also has its own fleet of around 4,000 wagons. The fleet grows by 200 new vehicles every year – lightweight and efficient, licensed for use in Europe and very quiet, thanks to their ultra-quiet “whisper brakes”.

Even if customs borders and technical restrictions no longer apply, there are still plenty of hurdles in terms of strengthening Europe’s rail cargo network. This starts with the capacity of the rail network. We already mentioned the tracks being blocked at the rehitching stations. In addition to this, the varying safety requirements must be taken into account. Having said that, a major milestone for more efficient, free-flowing freight transport is the ongoing, widespread introduction of the standardised European Train Control System (ETCS).

A lack of passing sidings and sidings that are not long enough are another challenge on the route. In fact, 720-metre container trains would be the aim for freight transport in the EU in order to make full use of the efficiency of rail freight. Unfortunately, the infrastructure only rarely permits trains of this length. On the regular Metrans route from Hamburg to Prague, trains of 680 metres (instead of 650 metres) are allowed with a special permit. Each of these trains replaces an average of 60 trucks on the motorway. Between Hamburg and Munich, trains with a length of 700 metres are even possible. But in order to reach the target of 720-metre trains across the board, it would be necessary to expand the network – a difficult process that will take many years.

Horinek’s experiences from his day-to-day work show that the European rail freight network has plenty of room for improvement. With more environmentally friendly rail routes, Metrans alone could potentially replace far more than the equivalent of 72,000 truck journeys every year between Prague and the North German ports that it currently does.

Sustainable logistics: HHLA Pure

With this product, HHLA makes climate-friendly transport and handling available to its customers.

Learn more about it