4.5 billion tonnes of goods are transported every year in Germany – more than 70 percent of it on roads. If rail is to have a better chance at being the carrier of the future, its 33,000-kilometre network must be used more intensively. Transport companies like Metrans and the booking portal modility are already on track with the first digital processes.

How do containers get from the port to their destination in the quickest and most environmentally friendly way possible? Dr Tjark Siefkes has a vision: A freight train leaves Hamburg at 330 km/h and heads south – autonomously, without a locomotive driver. Shortly before getting to Hannover, its four large-capacity freight cars separate. Two of them continue on to Braunschweig and the other two roll to autonomous loading and unloading areas in a futuristic-looking railway station concourse.

The concept is called Next Generation Cargo (NGT). Siefkes drafted it at the German Aerospace Centre. The former head of development at train manufacturer Bombardier is convinced that “if we want to increase capacity on the tracks and to decrease transport times, energy use, emissions and noise, we need concepts like this.”

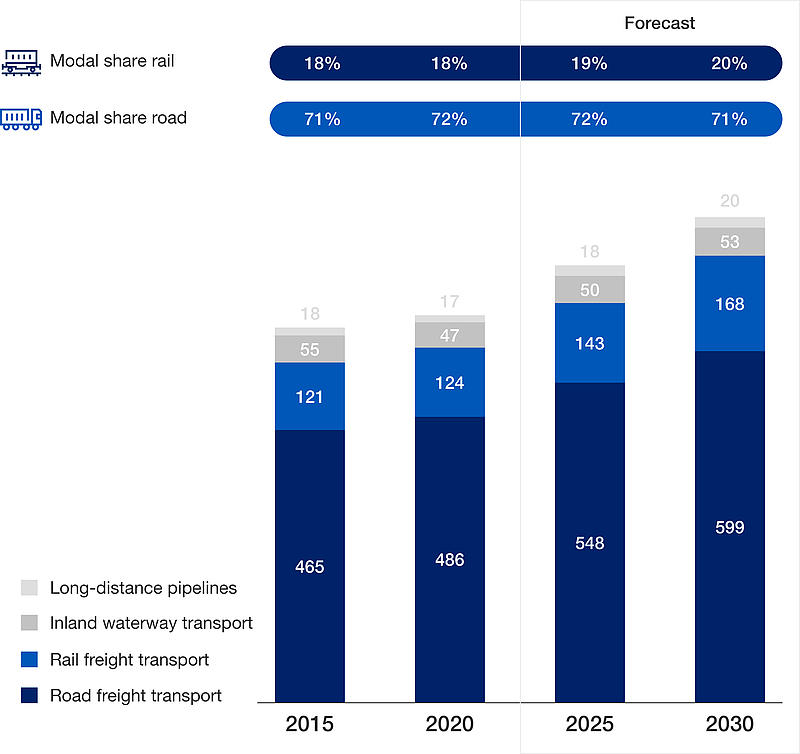

Against the backdrop of increasing volumes of transported goods, congestion on the roads, and the urgent need to reduce harmful emissions from truck transport, important courses must be set. The new federal government wants the share of freight traffic on the rails in Germany to grow from 19 percent currently to 25 percent by 2030. “We are running out of time in our effort to achieve our climate protection goals in the transport sector,” says Ingo Wortmann, President of the Association of German Transport Companies.

However, it’s doubtful whether rail growth can be achieved through political will alone. In its report on rail freight traffic in Germany in 2030 for the Association of German Transport Companies (VDV), management consultancy Roland Berger stresses that “it is becoming clear that, under current parameters, the envisioned target cannot be achieved.” Among other things, the Berger experts call for increased digitalisation of railroads.

Concepts for “digital railways in Germany” already exist

“We need more courage and speed with the implementation of innovations on German railways,” confirms Andre Rodenbeck, Chairman of the Rail Technology Steering Committee in the Deutsches Verkehrsforum and CEO of Rail Infrastructure at Siemens Mobility. He believes that concepts for “digital railways in Germany” already exist: “We can implement them successfully if we bundle and digitalise our planning and approval processes and adopt new collaborative approaches in the sector.”

In addition to expansion of the rail network and optimisation of it for longer freight trains, the federal government’s current Rail Freight Master Plan focuses primarily on projects that aim to automate and digitalise rail operations. Many rail transport companies such as HHLA subsidiary Metrans are already tackling this.

Metrans customers can use digital information to plan their containers to arrive “just in time”

All operational processes in the Metrans Group’s closely intertwined network of ports in the North and Adriatic Seas are controlled by standardised software. All trains are equipped with GPS and data portability so that the position of every loaded container can be seen at every stage of the journey between hubs and terminals in Germany, Austria, the Czech Republic, Slovakia, Hungary and Poland.

“This is especially important when time is of the essence,” explains Carsten Giesel, the managing director of Metrans Rail Deutschland. Customers can use digital information to plan their containers to arrive “just in time”. In Germany, Metrans is working alongside software developer RailWatch, a company that specialises in rail applications, to optimise the technical evaluations of freight trains.

Before every departure, wagons, cargo and the locomotive are subject to a visual check for damage. Night and day, whatever the weather, in ports, terminals, and on the private tracks of industrial operators, wagon technicians pace off the train. It’s a time-consuming job. The “DigiTwin” project is intended to shorten monitoring at certain transit stations by using digital picture recognition, sensors in the tracks and artificial intelligence.

Digital twins for train dispatch

RailWatch and Metrans Rail Deutschland are jointly developing a digital twin of a freight train to significantly speed up technical checks.

Learn more about the project

The innovative potential of rail-based freight transport is now successfully supporting new business ideas. modility, the booking portal founded by HHLA and partners, provides companies with uncomplicated access to combined transport on rails and roads.

Combined transport operators receive an additional online distribution channel which they can use to market their routes and remaining capacities at current prices and increase train capacity utilisation. Freight forwarders can use the platform to find combined transport connections and current offers, and to easily book the right transport option. modility’s success speaks for itself: 100 days after its launch, more than 100 companies had already registered. Nearly 100 train connections are already being marketed. 50 terminals in ten countries are now part of the modility network.

However, such successful projects and initiatives cannot conceal the fact that the basic requirements for digitalisation of the railways are only progressing slowly. The challenge is often that the technical solution must be usable and accepted throughout Europe. Otherwise, cross-border freight traffic is no longer possible.

Digital solutions must work throughout Europe

All the experts from the European Train Control System (ETCS) are expecting a major boost for freight traffic on rails. Until now, locomotive drivers have had to pay close attention to mechanical signals and slow down or stop their trains if necessary. In the future, this task will be taken over by an autopilot system that is guided by information from a digital monitoring network along the route.

The basic information for automatic control is supplied by so-called Eurobalises. These transponders, installed in the middle of the track, transmit information to the passing train about its location, the next signals, and current traffic information, among other things. For instance, prototypes of this technology are used to provide fast-moving trains with information regarding the proper automatic lateral inclination for their speed before they pass through a curve.

At the moment, only 340 kilometres of railway are ready for ETCS operation – that’s just one percent of the entire rail network. In addition, approximately 10,000 rail vehicles must be retrofitted with the necessary technology, which means they must be removed from operation for about a year.

A system like ETCS would be necessary to make Tjark Siefkes’ vision a reality. The vision he initially introduced, of trains and single carriages that drive autonomously, relies on digital control: therefore, the DLR expert doesn’t expect his Next Generation Cargo Train to pick up speed in the near future. Still, his technology could gain momentum soon: The DLR team will shortly be trialling a new kind of propulsion for a future train that will drive each wagon wheel individually and make a locomotive unnecessary.

Version from June 2022