Quicklinks

Quicklinks

Supply chain bottlenecks are affecting the global trade. Whether it’s microchips, wood or certain consumer goods, much is in short supply or sometimes unavailable. Consumers are waiting months for ordered goods, and manufacturers for intermediate products of all kinds. There are many causes of the disruptions, and all participants in the transport chains must work together to solve the problems. HHLA is making its contribution by providing additional yards for containers and by sharing data.

This effort must be taken on first and foremost in the political sphere, and it must work with the private sphere to get the massive disruptions in supply chains under control. Germany has been particularly hard hit by the supply chain problems. The proportion of foreign trade, i.e. the share of imports and exports in the gross domestic product, comes to 88 percent, according to DIHK. This is the highest of all the G7 states.

Solving the current problems is a challenging joint effort. It ranges from the scarcity of raw materials and personnel shortages to natural disasters and the closure of important transport routes, like the Suez Canal or, more importantly, railways and motorways in Germany.

German companies are feeling a significant increase in the bottlenecks, also as a result of the Russian invasion of Ukraine. In fact, around 60 percent of companies have reported additional disruptions in their supply chains and logistics, according to a survey conducted by DIHK.

Global logistics networks are susceptible to interference, but is that just a disadvantage of globalisation? Despite the current bottlenecks, Prof. Wolfgang Kersten, Head of the Institute of Business Logistics and General Management at the Hamburg University of Technology, says the international division of labour still holds up. He does not consider a universal recovery of international procurement to be either sensible or feasible.

Prof. Evi Hartmann from the University of Erlangen-Nuremberg agrees. She points out that supply chains aren’t strings of fairy lights that “one can turn off or on in a second. Finding and integrating alternative suppliers is an extensive process,” says the Chair of Supply Chain Management.

The prevailing logic of just-in-time warehousing has led to a lack of storage space for containers and also general cargo. “But companies can’t build up 20 to 30 percent more inventory in the short term for safety’s sake. In Germany, available storage space is now running out, approval procedures are taking too long and there is simply a lack of possible commercial sites,” says Hartmann.

For German manufacturing SMEs, many orders can’t be processed at all due to the shortage of raw materials. For some raw materials, the prices have absolutely exploded in the past few months. As a result, Stoffels (DIHK) says, it’s already a matter of survival for some SMEs. “They themselves have fewer intermediate products or – like energy supplies – are only getting them at too high a price.”

These cost increases can only be partially passed on to their customers, and, due to delays in their own supply chains, can only deliver at a steadily worse level themselves. And when the goods are ready, they may not be collected at all because there are too few locomotive drivers and truck drivers available.

The truck driver shortage is an especially urgent problem, which has been worsened by the war in Ukraine. According to DIHK, some 100,000 truck drivers working in Poland are from Ukraine. “They’re now no longer available.” According to the report, the share of Ukrainian drivers in Germany comes to around 7 percent. There is also the factor that forwarding and transport companies are under more cost pressure due to higher fuel and energy prices.

In air cargo, the closure of key airspace as a result of the Russian invasion of Ukraine has led to longer flight times, lower cargo capacity and higher jet fuel requirements. Further increases in transport costs and time lags in supply chains are expected in this sector as well.

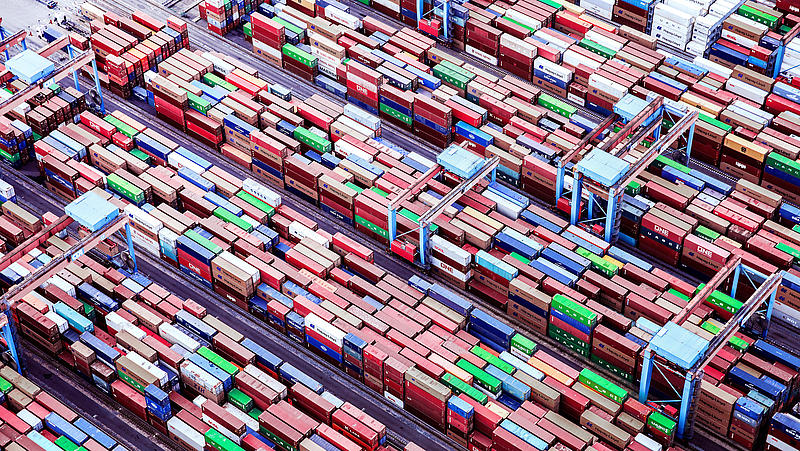

In the international exchange of goods, ships take on the large majority of goods transport. This makes seaports some of the central hubs of the global network. On many continents there are important transshipment hubs where previous delays, for example due to port closures or congestion on hinterland connections, are multiplied.

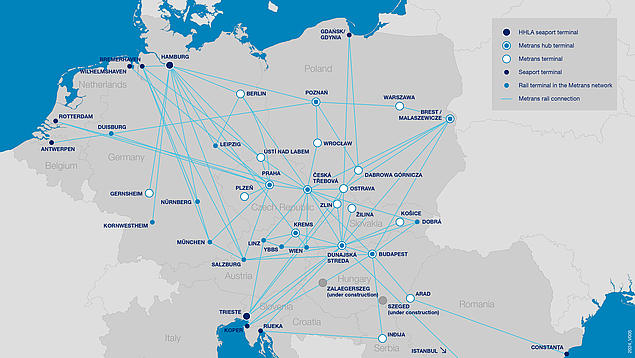

HHLA’s subsidiary Metrans provides highly frequent rail connections from the seaports on the North Sea and the Adriatic in order to serve the export-oriented economies of Central Europe. The company is the market leader for seaport-hinterland container traffic with Central, Eastern and South-Eastern Europe.

The throughput of goods, which are most often delivered in containers, takes time. The human resources here are also limited, or, during the pandemic, not always available. Angela Titzrath, Chairwoman of the Executive Board of Hamburger Hafen und Logistik AG, speaks of “mutually reinforcing factors”, that are shaking up a lot of things in the shipping industry.

At HHLA, she says, the most significant cause for the delay in handling ships is the lack of space for more containers. For a few weeks now, import containers have not been collected and have clogged up the container yards. Titzrath emphasises that HHLA is trying to take countermeasures. “We have created additional space to store containers, and we are trying to build up greater capacity by increasing flexibility and trying to manage exports and imports with everyone involved. But all ports need to do this equally, as do all those involved in the supply chain, on the water, on the road and on the railways.

An interview with Angela Titzrath, CEO of Hamburger Hafen und Logistik AG, on the bottlenecks in global trade, the future of globalisation and unloved garden furniture.

Gaby Bornheim, President of the German Shipowners’ Association, draws the same conclusion: “There is sand in the gears that we will only get out of the supply chains by working together.”

Prof. Dr.-Ing. Carlos Jahn recognises current difficulties, but he doesn’t want to overdramatise the situation. As the Director of the Institute of Maritime Logistics at the Hamburg University of Technology and Head of the Fraunhofer Center for Maritime Logistics and Services CML, he knows what’s going on. He says maritime logistics is a highly efficient, interdependent system. “Shipping companies, ports, logistics companies and service providers have worked well together for years – otherwise the chains wouldn’t work at all now. Cooperation is the foundation of maritime logistics.”

Jahn does not, however, deny that an important component was added in recent years: the sharing of data. “This is something very new, and even more willingness to cooperate would help here as well, to prevent minor disruptions in the supply chain from growing to the current dimensions in the first place.”

This article was produced with the support of DVZ Deutsche Verkehrs-Zeitung (German Transport Magazine) on June 21, 2022.

All information on the current trends automation, artificial intelligence, digitalized supply chains, drones and hydrogen as well as HHLA's projects.

Discover innovation at HHLA